Refrigerant Pressures

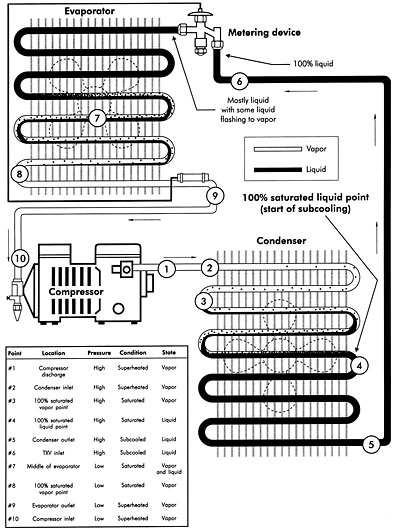

The typical vapor compression refrigeration system (as shown in Figure 1) can be divided into two pressures. They are condensing and evaporating - or high- and low-side - pressures. These pressures are divided or separated in the system by the compressor's discharge valve and the metering device.Listed below are field service terms or trade jargon often used to describe these pressures.

Condensing pressure: High-side pressure, head pressure, discharge pressure.

Evaporating pressure: Low-side pressure, suction pressure, back pressure.

Condensing Pressure

The condensing pressure is the pressure at which the refrigerant is phase changing from a vapor to a liquid. This phase change is referred to as condensation. Thus the term condensing pressure. This pressure can be read directly from a pressure gauge connected anywhere between the compressor's discharge valve and the entrance to the metering device, assuming that there is negligible pressure drop.In reality, line and valve friction and the weight of the liquid itself cause pressure drops from the discharge of the compressor to the metering device. If a true condensing pressure is needed, the technician must measure the pressure as close to the condenser as possible to avoid these pressure drops.

This pressure is usually measured on smaller systems near the compressor's valves. On these small systems, it is not critical where a technician places the pressure gauge as long as it is on the high side of the system because pressure drops are negligible.

The pressure gauge will read the same no matter where it is on the high side of the system if line and valve losses are negligible.

Evaporating Pressure

The evaporating pressure is the pressure at which the refrigerant is phase changing from a liquid to a vapor. This phase change is referred to as evaporation or vaporizing, thus the term evaporating pressure. A pressure gauge placed anywhere between the metering device outlet and the compressor will read the evaporating pressure. Again, negligible pressure drops are assumed.In reality, there will be line and valve pressure drops as the refrigerant travels through the evaporator and suction line. So, the technician must measure the pressure as close to the evaporator as possible to get a true evaporating pressure.

On small systems where pressure drops are negligible, this pressure is usually measured near the compressor. Again, on small systems, gauge placement is not critical as long as it is placed on the low side of the refrigeration system. This is because the refrigerant vapor pressure acts in all directions equally.

However, line and valve pressure drops are assumed to be negligible in this simple system. If line and valve pressure becomes substantial, gauge placement becomes critical. The larger and more sophisticated the system, the more critical gauge placement becomes because of associated line and valve pressure losses.

If the system has significant line and valve pressure losses, the technician must place the gauge as close as possible to the component that he wishes to read the pressure from.

Refrigerant States

Modern refrigerants exist in either the vapor or liquid states. Refrigerants have such a low freezing point that they are rarely in the frozen or solid state. Refrigerants can coexist as a vapor and liquid as long as conditions are right.

Both the evaporator and condenser house liquid and vapor refrigerant simultaneously if the system is operating properly. So, refrigerant liquid and vapor can exist in either high- or low-pressure sides on the refrigeration system.

Refrigerant Conditions

Along with refrigerant pressures and states, there are refrigerant conditions. Refrigerant conditions can be saturated, superheated, or subcooled.Saturated condition: Saturation is usually talked about in reference to a temperature. The saturation temperature is the temperature that a fluid will phase change from liquid to vapor or vapor to liquid. Both the liquid and vapor at their saturation temperatures are called saturated liquid and saturated vapor respectively.

Saturation occurs in both the evaporator and condenser since phase changes experiencing both liquid and vapor are present here. At saturation, the liquid is experiencing its maximum temperature for that pressure, and the vapor is experiencing its minimum temperature for that pressure. However, both liquid and vapor are at the same temperature for a given pressure when saturation occurs.

An exception to this would be some refrigerant blends. (As a reminder, this column is addressing refrigerants that exist as pure compounds, such as R-134a.) Saturation temperatures vary with different refrigerants and rely on the pressure that the refrigerant is exposed to.

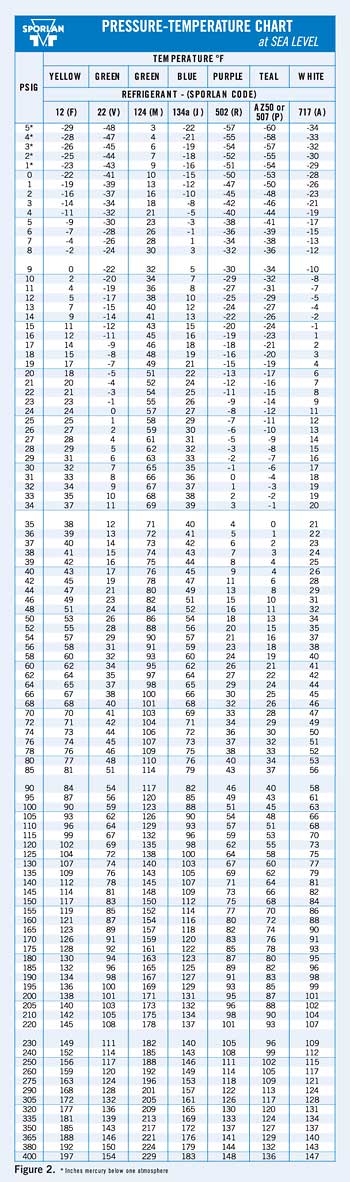

All refrigerants have different vapor pressures. It is vapor pressure that is measured with the technician's gauges.

Vapor pressure is pressure exerted on a saturated liquid. Any time there is saturated liquid and vapor together, as in the condenser and evaporator, there will be vapor pressure present. Vapor pressure acts equally in all directions and affects the entire low or high side of a refrigeration system. As pressure increases, saturation temperature increases. As pressure decreases, so does saturation temperature.

In fact, only at saturation are there pressure-temperature relationships for refrigerants. Temperature-pressure charts (such as the one shown in Figure 2) show pressure and temperature relationships at saturation.

In fact, if one attempts to raise the temperature of a saturated liquid above its saturation temperature, vaporization of the liquid will occur. If one attempts to lower the temperature of a saturated vapor below its saturation temperature, condensation will occur. Both vaporization and condensation occur in the evaporator and condenser respectively.

The heat energy that causes a liquid refrigerant to change to a vapor at a constant saturation temperature for a given pressure is referred to as a latent heat process. Latent heat is heat energy that causes a change in phase of a substance without a change in the temperature of the substance. Phase changes go from liquid to vapor, or from vapor to liquid.

Vaporization and condensation are examples of a latent heat process. Both vaporization and condensation occur in the evaporator and condenser respectively.

Superheated condition: Superheat always refers to a vapor. A superheated vapor is any vapor above its saturation temperature for a given pressure. In order for vapor to be superheated, it must have reached its 100 percent saturated vapor point.

In other words, all of the liquid has to be vaporized for superheating to occur. The vapor must be removed from contact with the vaporizing liquid. Once all of the liquid has been vaporized at its saturation temperature, any addition of heat will cause the 100 percent saturated vapor to start superheating.

This addition of heat will cause the vapor to increase in temperature and gain sensible heat. Sensible heat is heat energy that causes a change in the temperature of a substance.

However, before a vapor can reach the superheat state, it must be physically removed from the vaporized liquid. Superheat vapor occurs in the evaporator's outlet, suction line, and compressor.

The heat energy that superheats vapor and increases its temperature is referred to as sensible heat energy. Superheating is a sensible heat process.

Subcooled condition: Subcooling always refers to a liquid at a temperature below its saturation temperature for a given pressure. Once the entire vapor has phase changed to 100 percent saturated liquid during saturation, the further removal of heat will cause the 100 percent liquid to drop in temperature or lose sensible heat. Subcooled liquid is now formed. Subcooling can occur in both the condenser and liquid line and is a sensible heat process.

Sidebar: What's In A Word?

Here is a summary of some of the definitions used in this column.Condensing pressure: The pressure at which the refrigerant is phase changing from a vapor to a liquid.

Evaporating pressure: The pressure at which the refrigerant is phase changing from a liquid to a vapor.

Latent heat: Heat energy that causes a change in phase of a substance without a change in temperature of the substance.

Saturated temperature: The temperature that a fluid will phase change from liquid to vapor or vapor to liquid.

Sensible heat: Heat energy that causes a change in the temperature of a substance.

Subcooling: A liquid at a temperature below its saturation temperature for a given pressure.

Superheated vapor: Any vapor above its saturation temperature for a given pressure.

Vapor pressure: Pressure exerted on a saturated liquid.

The second installment of this series on refrigerants is scheduled to appear in the June 6 issue of The News. The third part is scheduled for the July 4 issue.

John Tomczyk is a professor of HVACR at Ferris State University, Big Rapids, Mich., and the author of Troubleshooting and Servicing Modern Air Conditioning & Refrigeration Systems, published by ESCO Press. To order, call 800-726-9696. Tomczyk can be reached by e-mail at tomczykj@tucker-usa.com.

Publication date: 05/02/2005

Report Abusive Comment