Air is invisible. Distribute excessive conditioned air into an unoccupied area, and we hardly even notice. But, if air were water…

Imagine that Mr. and Mrs. Jones live in a 1,500-square-foot ranch home. The one and only water shutoff in the entire house is located in the basement. When Mr. Jones wishes to flush the toilet, he must yell for Mrs. Jones to run down to the basement and turn the water on. When she does, water pours out from the pipes running to showers, sinks, and spigots. (Remember, there are no shutoffs anywhere.) Whenever they need water from one faucet, the whole house gets a soaking. Sounds pretty absurd, doesn’t it? This is precisely what happens to conditioned air in every system that does not have zoning. Energy is being wasted to condition air that is delivered to unoccupied areas.

Zoning is a simple, effective way of increasing your customers’ comfort and helping to reduce their utility bills.

In addition to occupancy issues, zoning can increase comfort in situations where temperature fluctuations occur from solar gain, outdoor shading, lack of insulation, dwelling construction, remodeling, multi-level houses, and directional exposures.

LAYING OUT THE ZONES

Zones should be set up according to the occupants’ usage and load demands. A typical grouping would be:Zone 1 — Living and dining room;

Zone 2 — Master bedroom;

Zone 3 — Family room and kitchen;

Zone 4 — Upstairs bedrooms;

Zone 5 — Basement;

Zone 6 — Home office and library.

Always separate upstairs and downstairs zones. Similar usage areas with different sun exposures may require separate zones, as well as rooms of different construction types.

COMPONENTS OF THE SYSTEM

Main Controller— It is generally used when two or more zones are being controlled. On a call for heating or cooling, a thermostat or sensor sends a signal back to the controller for processing. An action to open, close, or modulate the damper is initiated, and an electrical or pneumatic signal is then sent to the damper. The controller regulates heating, cooling, fan, and auto-changeover. In addition, it determines heating and cooling priorities per zone and has night setback capabilities.Slave Control — Action is initiated by a thermostat that controls only the damper. It does not regulate heating or cooling.

Air Damper — Driven either electrically or pneumatically, a gasketed piece of metal closes, opens, or modulates to control airflow.

Thermostat — A thermostat is located within the zone. It sends a signal to the main controller to initiate heating, cooling, fan, or auto–changeover.

Leaving Air Temperature Controls — These controls prevent excessive discharge air temperatures that may be caused due to closed dampers and where the supply is bypassing directly into the return air.

BYPASS SYSTEMS

When multiple zone dampers are closed in a system, excessive static air pressure builds up within the ductwork. This condition has the potential to cause excessive noise. A bypass system relieves the excessive air pressure. The following are four examples of bypass systems.Barometric Dampers — This system bypasses air to the return side of the system by maintaining a certain pressure differential between the supply and return.

Wild Zones — Excessive air is dumped in areas that are not subject to overheating or cooling. There are no control dampers in the ductwork supplying these areas.

Blow-by Dampers — Slightly undersized dampers allow air to bleed through, thereby reducing air pressure buildup.

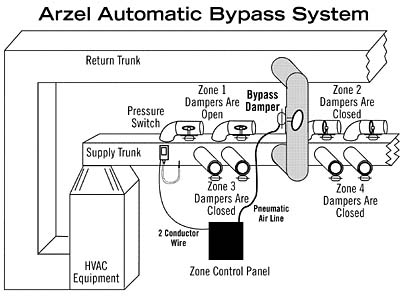

Automatic Bypass System — A pressure switch monitors the static air pressure within the duct system and relays a signal to open or close a bypass damper upon static pressure buildup. Conditioned air is bypassed from the supply back to the return side of the system, ideally as far away from the equipment as possible.

Rothacker is a director of area51hvac.com. For questions or comments on the Tech Page, contact Rothacker at ewizaard@hotmail.com (e-mail).

Publication date: 09/23/2002

Report Abusive Comment