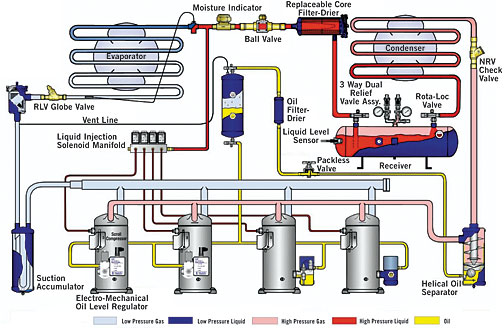

One of the main advantages of parallel compressor systems is their ability to closely match the refrigeration load. Parallel systems apply two or more compressors to a common suction header and a common discharge header. (See Figure 1.)

Under high evaporator heat loading, all compressors may be operating. As the evaporator's heat load decreases, compressors will start to cycle off. A pressure transducer connected to the common suction header and hardwired to a microprocessor senses the ever-changing refrigeration load.

Whether all of the compressors are operating or just one, the common discharge header must handle the entire volume of the compressors' oil-laden discharge gas. This common discharge header must be sized so that it is large enough to handle all of the compressors operating at once. This common discharge header will experience a variety of refrigerant flow rates and velocities, depending on the number of compressors operating.

Under low evaporator load conditions, however, only a few compressors will be running and the refrigerant flow rate and velocity will be low.

Low Evaporator Loading

One of the main conditions that causes oil to flow through a refrigerant line is the velocity of the refrigerant inside the line. Under these low evaporator loadings, when only a few compressors are operating, the refrigerant velocity in the common discharge header will be at its lowest.This causes the oil to creep along very slowly. It may eventually accumulate in the common discharge line, which is actually oversized when only a few compressors are operating. This is why an oil separator is the first component the compressor's oil-laden discharge gas will come across.

The oil separator separates oil from the hot discharge refrigerant gas. It also traps oil in a sump and sends it by differential pressure to an oil reservoir. A pressure valve in the line connecting the oil reservoir and the common suction header keeps the oil reservoir at about 20 psi above the common suction pressure.

From the oil reservoir, the oil must feed each individual compressor as it demands. However, parallel compressor systems have always had a problem when it comes to maintaining the correct oil level in each compressor.

Electronic Regulation

An innovative and accurate technology uses optics to electronically regulate and control the level of oil in the compressor's crankcase. This type of oil regulating unit senses the oil level in the compressor's crankcase by sensing light refracting through a glass prism.The oil level in the compressor's crankcase is regulated half-way up the compressor's oil sight glass using a light beam and a pulse timer. (See Figure 2.) This electronic, optical oil level regulator unit can be fitted to the sight glass housing on the compressor and has its own built-in sight glass. The technician can visually inspect the crankcase oil level.

This system can be used for high- and low-pressure oil management control systems.

When a low oil level is detected, a 15-second time delay from low oil level detection to oil feeding prevents overfilling the crankcase with oil. Once the 15-second time delay has run its course, if there is still a need for oil in the compressor's crankcase, oil is pulsed electronically into the crankcase at three-second on-off intervals. The pulsing helps ensure a more accurate fill and reduces the risk of foaming inside the compressor.

If the compressor's crankcase is not satisfied at the sight glass's one-half level after two minutes of oil pulse feeding, an alarm is initiated electronically. During this alarm condition, the electronic optic oil level regulator will continue to pulse-feed oil into the compressor crankcase.

Once the proper oil level is reached in the compressor's crankcase, the low-oil alarm automatically resets. The alarm's contacts can be easily wired to a control panel and used to shut down the compressor in case a complete oil loss ever occurs.

John Tomczyk is a professor of HVACR at Ferris State University, Big Rapids, Mich., and the author of Troubleshooting and Servicing Modern Air Conditioning & Refrigeration Systems, published by ESCO Press. To order, call 800-726-9696. Tomczyk can be reached by e-mail at tomczykj@tucker-usa.com.

Publication date: 12/06/2004

Report Abusive Comment