A predictive approach can be applied to any equipment problem if, first, a physical parameter like vibration, temperature, pressure, voltage, current, or resistance can be measured. An engineering limit for the measured physical parameter must be established so a problem can be detected during routine monitoring. Also, the limit should be low enough to detect the problem before destructive damage occurs. Correcting the root problem is the key to most predictive efforts.

By helping your customers apply the predictive approach to maintenance, downtime can be avoided and costs can be reduced. The advantage to the service contractor is that maintenance work can be planned and performed on a regular schedule.

The PDM Cycle

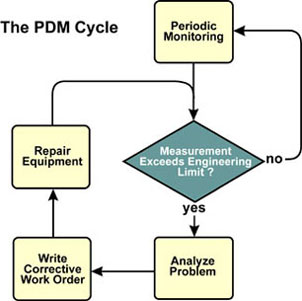

Once a new piece of critical equipment has been added to the program and baselined, it enters the PDM cycle, graphically shown at right.The established parameters are measured periodically (weekly, biweekly, monthly, etc.). If the measurement exceeds the established engineering limit, it must be analyzed further.

Analysis can take many forms. For example, a vibration signature can be taken on rotating equipment, such as a motor or blower. A trained analyst may review the signature for common problems, such as misalignment and imbalance, as well as for not-so-common problems, like resonance.

Once the source of the problem is determined, the best repair activity can be chosen. If the engineering limit is set low enough, there will still be plenty of time to correct the problem before further damage occurs.

Correction of the root problem allows the equipment to re-enter the periodic monitoring program.

The Spectrum Of PDM

There has been a historical misconception that equipment failures cannot be predicted. However, with predictive technology, a vast number of equipment failures can be predicted. Vibration measurement on rotating equipment is probably the best known of current predictive applications, but other categories of commercial and industrial equipment also benefit from a predictive approach. (See Table 1.)

The Mortality Of Machinery

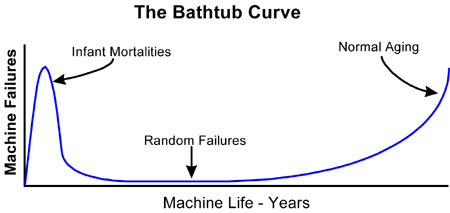

Researchers into the reliability of equipment recognize that within a collection of machines there is a definite pattern of life spans. In practice, this pattern manifests itself when a collection of machinery is subjected to rigorous operation. The plot of typical life spans is shown in the so-calledbathtub curve.

Among collections of equipment, there is a rather high incidence of early failures, called infant mortalities. Most equipment that survives infancy will continue to perform with few failures occurring. In time, however, the failures begin to increase until the last of the group succumbs.

Finding The Parameters

The failures that form the latter part of the curve are caused by identifiable physical phenomena. Depending upon the complexity of the machine, there may be several aging processes at work in a single piece of equipment, any of which may cause the ultimate failure. These processes are usually related to the basic physics of the materials and how the machine is used.Knowledge of the physical properties of materials comes from either theoretically or empirically derived conclusions. To understand how failures can be predicted, the mortality of machinery and the finding of parameters need to be understood.

For example, Ohm's law and the theory of potential difference follow theoretically from Maxwell's equations for electromagnetic fields and define the nature of electrical current in conductors and insulators. By contrast, many parameters used to predict failures follow from empirical studies and the application of statistical analysis to actual failures. For example, experiments in the 1930s showed that measurement of forces on bearings can be accomplished by measuring the total movement of the machine during operation along with the speed of this movement. Of course, this movement is vibration. Thus, forces on bearings can be determined by measuring vibration at or near the bearings.

Defining Limits

The measurement of a physical parameter in itself is not enough to detect the destructive effects on a machine or process. As noted, it is important to establish a limit or rate of change in the parameter that may be excessive or damaging.One method of developing a limit requires that a number of failures be observed before a safe limit is established. This method is understandably objectionable to people operating a facility. Prudent management of a PDM program requires that limits be tested at the same time as the monitoring of other factors on a device. Whenever time permits, the device in question is taken out of service and thoroughly inspected for the defect or failure mode in question. Ideally the limit will be set at a measurement value just below the point corresponding to the first discovery of irreparable or costly defects.

Many engineered limits have already been established for equipment by manufacturers, professional societies, and industrial groups. For example, the Vibration Institute, a not-for-profit professional organization, and other organizations have established levels of equipment health as a function of vibration velocity based on experiments. A simplification of this equipment health data is shown in Table 2. This table is useful for categorizing vibration levels on most commercial/industrial equipment operating between 600 rpm and 3,600 rpm.

By applying these existing limits, service contractors and facility managers can readily apply PDM to critical equipment and begin experiencing the cost efficiencies of the predictive approach.

Michael V. Brown is president of New Standard Institute Inc., Milford, Conn. New Standard Institute provides seminars, computer-based training programs, and consultations in the field of maintenance management and improvement. For more information, call 888-783-1582, e-mail nsi@newstandardinstitute.com, or visit www.newstandardinstitute.com.

Publication date: 06/02/2003

Report Abusive Comment