K-Pac's 18-acre development offers an array of transportation services to importers, exporters and domestic shippers of refrigerated commodities. Core services include cold storage, distribution, transloading, USDA inspection, Electronic Data hiterchange (EDI), off-dock container freight stations, computerized inventory management and direct rail service via Union Pacific/Southem Pacific and Burlington Northem/Santa Fe railroads.

In 1999, K-Pac California realized that by upgrading its cold storage facility with desiccant dehumidification numerous operations problems due to high humidity levels could be alleviated.

K-Pac California Facility Design

The K-Pac facility was constructed using a "rack-supported" design or built from the inside out. The K-Pac freezer building measures 120,940 square feet and includes two small coolers to temper fruits and vegetables and one large freezer for storage of frozen foods and blast freezing of unfrozen foods. The K-Pac facility has 28,935 square feet of chilled capacity and 92,005 square feet of frozen capacity. The coolers have a 65-degree temperature rance between minus 30 degrees Fahrenheit and plus 35 degrees Fahrenheit, depending on product cooling needs, while the large freezer is maintained at a constant minus 30 degrees Fahrenheit. The combined freezers offer a total of 26,000 pallet positions. They house a variety of refrigerated commodities including meat, poultry, seafood, as well as an assortment of fruits and vegetables.

Humidity Control a Necessity

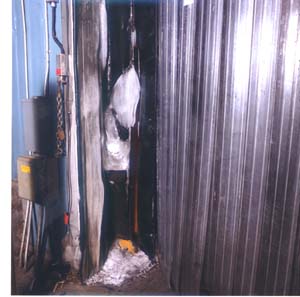

Humidity is a problem for any cold storage facility. Moisture condensation causes ice to form on floors and doors and slows down loading and unloading operations. Additionally, employees can slip and fall on the ice, leading to costly injuries. The ice that forms must be chipped or melted off by hand - a time-consuming job for workers - an added labor cost for the cold storage company."Whenever you have a big temperature differential you automatically have high humidity," said Bill Johns, Facility Manager for K-Pac. "We were seeing a lot of ice and frost build up on and around our freezer doors because of the high humidity. This extra moisture increased our defrost cycles. On a regular basis, we had to use ice chippers to remove the ice from around the doors."

Employee safety was another issue that K-Pac faced because of high humidity levels.

"Ice that formed on the floor made it difficult for our forklift operators to brake on the slippery surface. This slowed down loading and unloading operations," added Johns. "The efficiency of our operations and safety of our employees were definitely being affected by the humidity levels."

K-Pac also realized that they could reduce energy costs if they purchased a system to help take the water load out of the air. With a dry loading dock, refrigeration coils operate more efficiently and defrost less frequently, reducing electrical power costs. K-Pac decided to take action.

"We received a mailer about desiccant dehumidification for refrigeration plants from Munters in February of 1999 and decided to respond to it," said Johns. "We spoke with Munters engineers who invited us to stop in for a demonstration."

After speaking with Munters engineers, in June 1999, K-Pac decided they would like to perform their own demonstration at the plant.

"We ran the demonstration unit for three or four weeks in June and part of July," said Johns. "The Southern California Gas Company monitored the loading dock temperature and humidity during the demonstration and participated in the evaluation."

After the demonstration, the gas company and Munters then presented their proposals to move forward with two Munters FreezAire units. Near the end of 1999, K-Pac managers approved the proposal for installation of a FreezAire F30, a FreezAire F10 and a gas driven engine at the facility.

In May 2000, installation of the units was completed. The F30 unit was mounted on the roof at the north end of the facility above the loading dock with a weather-tight seal and thermal barrier and the F IO unit was installed on the smaller south dock of the facility. The gas driven engine is currently going through a fine-tuning process to pass AQMD testing. Once it is certified for operation, the exhaust heat from the gas driven engine will be used to heat water and for preheating of the reactivation air of the F IO unit. When the hot water is available it will reduce the load for the reactivation air gas burner and save energy.

"We hired outside contractors to perform the installation of the Munters FreezAire units, and it took them about three days to install them," said Johns. "Munters technicians did the start up for us and was very responsive and knowledgeable about our specific application. This is the first installation of its kind in Southern California."

What is Desiccant Dehumidification?

Unlike refrigerant-based dehumidifiers that cool the air to condense moisture and then draw it away, desiccants attract moisture from the air by creating an area of low vapor pressure at the surface of the desiccant. The pressure exerted by the water in the air is higher, so the water molecules move from the air to the desiccant to make the air drier.In Munters' FreezAire(E desiccant dehumidification systems, the desiccant support structure is a HoneyCombeg wheel. The desiccant -- in this case, a titanium-enhanced silica gel -- is infused into a corrugated composite material that resembles the honeycombs of a bee hive and this is formed into a wheel.

The system handles a mixture of fresh air and returned inside air, removing moisture before it drifts into freezers. As the moist air passes through the slowly rotating 60" diameter desiccant wheel (8-12 rotations per hour), the moisture is absorbed, leaving dry air. The dry air is then delivered to the loading dock via a process fan, while the moisture is simultaneously collected and released from the wheel as the wheel rotates into a heated reactivation section. A "double wall" design prevents condensation and air leakage from occurring on or within the dehumidifier cabinet.

The FreezAire F30 supplies 10,000 standard cubic feet per minute (SCFM) of dry air at 5.5 grains per pound or a 0 degree Fahrenheit dew point. The system is designed to remove about 270 pounds/hour of moisture without needing to defrost.

"We designed the FreezAire units to provide a quick and easy solution to moisture problems in refrigerated storage operations," said Peter Dahlbeck, district manager for Munters DH Division. "The units were specifically developed to improve safety conditions and product quality, increase efficiency and decrease facility utility costs."

Benefits of Installing Desiccant Dehumidification at K-Pac

According to Johns, the Munters dehumidifier is performing as planned. "We noticed the benefits of installing the FreezAire F30 system during the first week," said Johns. "Currently, the loading dock is maintained at 50-55 degrees Fahrenheit and the humidistat is set at 40 percent relative humidity (RH). The unit cycles on and off and keeps the RH between 40-50 percent by the freezer doors, right where we want it to be. With this system, relative humidity should remain between 40 and 50 percent throughout the year."By removing moisture from the air in loading dock areas and preventing humidity from condensing on floors or invading storage areas, the Munters FreezAire units have increased the efficiency and safety of operations at K-Pac.

"The forklifts brake much better with dry floors and they run a little faster now," said Johns. "And icicles and snow no longer develop on the ceiling.

"In addition to providing a safer working environment for employees the units have decreased truck loading and unloading times by keeping the loading dock dry, and improved product quality by preventing frost build-up through consistent temperatures," said Johns. "And with the FreezAire units, there's less of a need to defrost because moisture is removed through desiccant attraction, rather than through condensation.

According to Johns, the units also have required very little maintenance.

"Except for changing the filters, the units have required very little attention from us at all," said Johns. Although it is too early to tell, K-Pac engineers hope to see a reduction in energy costs in the near future. "We are very pleased with the performance of the Munters dehumidifiers," noted Johns. "We are already considering adding another FreezAire unit to an uncontrolled loading dock on the other side of our building that is frequently opened during the week."

For more information, contact Munters Corp. - Dehumidification Division at 79 Monroe Street, P.O. Box 640, Amesbury, MA 01913; 978-241-1100 or 800-843-5360; www.muntersamerica.com.

Publication date: 05/14/2001

Report Abusive Comment