IAQ is a major concern because younger students, in particular, have less developed immune systems and they spread a lot of germs; staff has a different perception of comfort from room to room; doors are opened and closed throughout the day - every hour students pour through the hallways, creating strong airflow patterns. The maintenance staff may or may not fully understand the needs of the HVAC system, and chances are the staff is stretched thin; is maintenance being performed often enough, or at all?

It all seems to come back to the budget. Energy prices are hitting every building in North America, and schools are no exception. Energy will take a bigger chunk of the budget, and the money has to come from somewhere.

"Salaries and energy costs are among the top expenditures for schools," said Chris Coker, commercial marketing manager - New Products, Emerson Climate Technologies, Copeland A/C Division. "Helping school systems lower their operating costs allows them to spend more of their budgets hiring quality teachers."

Schools really ask for a lot from their HVAC systems, said Bart Powelson, director - Commercial Air Conditioning Marketing, Emerson Climate Technologies, Copeland A/C Division. "Make it simple, make it cost effective, make it healthy, make it comfortable, and make it work year round." There is a premium on reliability, improved diagnostics, and the ability to quickly resolve problems.

ENERGY AND MAINTENANCE BUDGETS

Schools have already been energy conscious, but are they aware of the ramifications of maintenance practices on the energy budget?According to "School Operations and Maintenance: Best Practices for Controlling Energy Costs," from the U.S. Department of Energy (DOE) Office of Energy Efficiency, "Operations and Maintenance (O&M) offers not only strategies for maintaining facilities, but also opportunities for reducing energy costs and increasing energy efficiency at existing schools, regardless of age."

According to the guidebook, enhancing O&M practices in K-12 school districts can reduce energy costs up to 20 percent. It just might keep the energy budget in line with previous years' expenditures, even if it doesn't result in a budgetary windfall.

"Each year, school districts are faced with tough decisions on how and where to cut costs to meet tight budgets," the guidebook states. "Increasing costs of energy and replacement of equipment continually generate problems for school districts' budgets. Nationwide, schools spend $8 billion per year on energy." Because this document was published in 2004, we can safely assume that the figure is probably lower than today's energy expenditures.

That $8 billion only represents 2-4 percent of school district budgets, according to the DOE. "Therefore, school administration officials may be tempted to pay little attention to managing or monitoring energy costs at the facility level. However, as a percentage of manageable costs, energy costs are more prominent.

"By implementing energy-efficient operations and maintenance strategies, school districts can generate substantial energy cost savings, extend the life of equipment, and improve the overall physical environment in their school facilities."

Strategies range from relatively simple, no-cost measures to more complicated strategies with higher first costs.

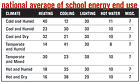

As you probably guessed, "Space conditioning ... accounts for the majority of school energy end-use." (See Table 1).

The DOE guidebook categorized energy-saving strategies as:

MANAGING LOADS

Scheduling equipment run times is one option; the use of variable-capacity mechanical systems offers another way to manage varying loads."Cooling is needed only when classrooms are occupied, and classrooms are occupied only at certain times of day," pointed out Coker. "Fixed-capacity systems handle this load variability inefficiency by cycling on and off."

Components such as modulating scroll compressors, specifically the Copeland® Digital Scroll® and Ultratech™, are designed to automatically adjust output to the cooling demand at a given time, he said.

"This leads to systems that can adjust to highly varying cooling loads. It also leads to better energy efficiency because the compressor requires less electricity when the heat load is less."

Such products "match output to whatever the heat load or cooling load is at any time," said Powelson. "A standard system may overcool or undercool. From an energy cost perspective, it will save the maintenance manager on his energy budget. There are fewer cycles on other parts of the systems.

"Any savings that you can get on those costs can go towards what's more important," he said. "I doubt that the budgets will keep up with rising energy costs."

WHEN MAINTENANCE ISN'T ENOUGH

When maintenance and energy bills start to outweigh the cost of a new HVAC system, however, it's time to start thinking about updating the old system. According to Coker, "The fluctuation of gas prices is also moving the market toward more heat pump systems." He pointed out that the company's new scroll products are designed to be used in either heat pump or cooling-only applications.When Smith Air Conditioning, in Ville Platte, La., equipped Sacred Heart Catholic School with a new HVAC system, it saved the school thousands of dollars.

"The school's 20-year-old HVAC system used water chillers for cooling and a boiler for heating, and it presented many climate and maintenance problems," said Ruse Smith, owner and operator of Smith Air Conditioning. "The building needed heating in the morning and cooling in the afternoon. Temperature changeovers took a long time, and individual classrooms did not have individual control. When teachers opened doors to cool classrooms, humidity trickled in and ceilings turned brown with mold."

The main problem with the old HVAC system was that maintenance bills totaled nearly $30,000 the previous year. The decision was made to use heat pumps in the classrooms and rooftop units from Lennox to utilize existing ductwork and gas piping in the 20,600-square-foot school's gym, stage, and foyer areas.

Five 10-ton gas packaged units were installed over the gym and stage areas, and a 5-ton unit was used in the foyer. In the smaller classrooms, eight split heat pumps were installed. All units were configured to fit the existing ductwork, according to Smith. Each classroom has an electronic thermostat to help regulate temperature; thermostats controlling the stage, gym, and foyer have remote sensors installed in the principal's office.

"Smith gave us a great presentation and bid for the system changeout," said Steve Benson, chairman of the facilities committee for the Sacred Heart school board. "His crew was very conscientious and did a great job. They even offered superior maintenance service and training for our janitors to prevent problems from occurring."

Making sure the staff has enough knowledge to maintain the system, or at least know when they should call for outside help, can offer tremendous cost savings for schools. Smart system diagnostics, such as the Emerson Comfort Alertâ„¢, can help a busy maintenance staff or HVAC contractor find the source of a system problem quickly. Flashing light diagnostics help a potentially undertrained maintenance staff solve the problem correctly the first time.

"It's not a cure-all, but it's helping the contractor or technician get it right the first time," said Coker. "Not only that, but in a lot of cases you have a general mechanical contractor who's responsible for a whole number of areas."

THE BUDGET VS. IAQ

Humidity and mold control carry their own price tags. School districts have become very much aware of the costs of mold litigation and remediation; it isn't quite so much of a battle to get humidity-control products worked into the budget."In my job, I'm in schools frequently, and the air conditioning is running year-round," Coker said. "It's a vastly different load. I suspect that they're not doing this to keep the janitor and staff comfortable; there are IAQ reasons." A variable-capacity system can run the system on low speed, which helps control humidity without keeping the building unnecessarily cold.

"There are also benefits from an energy cost standpoint," he said. "It can run more continuously rather than on and off, on and off," and the reduction in cycling helps the system's longevity.

Keeping the system operating to control humidity seems counterintuitive to staying within the energy budget. Good IAQ requires a delicate balance between comfort and efficiency.

That was the case for the Middle School Seventh/Eighth Grade Center in the Missouri Raymore Peculiar School System. Remodeling and expansion began in 1999. In areas such as the gymnasium and multipurpose room, where many active students flowed in and out each hour, more fresh air was needed to maintain standards set by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE).

"We needed to decrease the extreme temperatures outside the building to maintain an even climate control and bring more fresh air in for the students," said Joe Coon, Raymore Peculiar School System HVAC service engineer and technician. "The oxygen levels had to increase, but we needed to minimize energy use at the same time."

An energy recovery system (ERS), with the help of an energy recovery wheel, transfers heat and humidity from incoming outside air to the exhaust air in the summer, increasing the overall efficiency of the entire system. In the winter, it preheats outside air and adds moisture.

At Raymore, Coon and Jack Harris, director of building grounds, chose the ERS offered with L Series® packaged rooftop units from Lennox. The annual energy cost for an average Midwestern school facility's HVAC system totals $20,000. L Series units with an ERS save 30-50 percent of that cost; an estimated $10,000 annual savings, according to the manufacturer.

STRIKING A BALANCE

According to rooftop unit manufacturer AAON, "The ideal condition for comfort and the prevention of mold growth within a building is 75°F dry bulb with 35-50 percent rh. A conventional on-off rooftop unit is not capable of effectively controlling both the relative humidity and the dry bulb temperature under part-load conditions."The company's Digital Precise Air Control (D-PACâ„¢) system combines the benefits of the return air bypass configuration with modulating hot gas reheat and a variable-capacity compressor. "With the addition of a DDC package, an air-side economizer with three separate sections all individually controlled, the D-PAC system is the most energy-efficient method to control relative humidity and dry bulb temperature under all load conditions."

The system uses a smaller unit to control temperature and humidity. Return air flows into the unit. A return air bypass damper allows a portion of the return air to bypass the cooling coil. The remainder of the return air enters an economizer section, where it mixes with outside air. The mixture of outside and return (mixed) air then flows through the cooling and reheat coils. The bypassed and mixed airstreams combine downstream of the cooling and reheat coils. The combined airflow enters the fan, then discharges the unit through the final heater.

In order to provide precise airflow control through the return air bypass and the cooling coil, the three damper sections are independently controlled, the company said.

Summertime classes and out-of-session school usage have become more common in public schools, especially those with data learning centers. Regular classes themselves have generally resumed by the end of august, in areas where temperatures might not cool down until well into September or October, depending on the region of the country.

""We're all keenly aware of the heat out there," said Powelson. "We want kids and teachers to be comfortable and healthy."

Visit www.lennoxcommercial.com, www.aaon.com, and www.emersonclimate.com.

Publication date: 08/07/2006

Report Abusive Comment