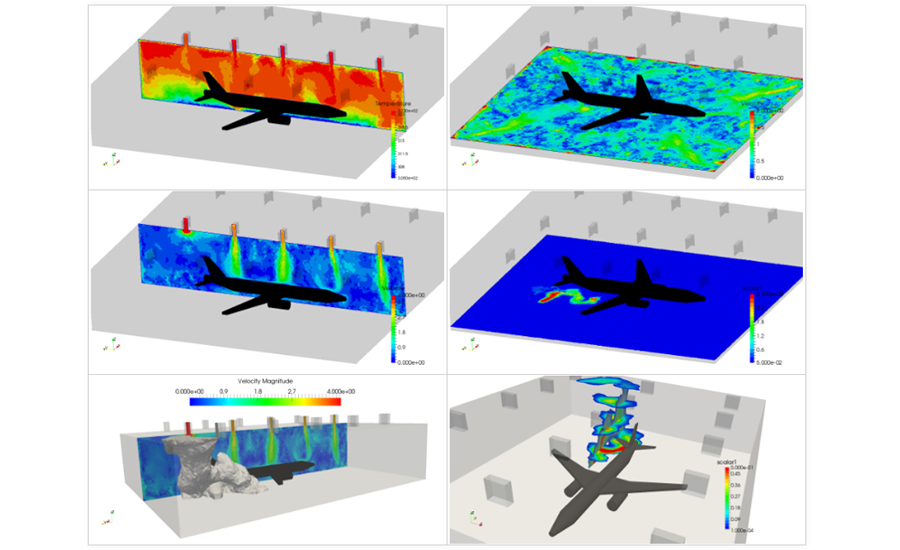

Computational fluid dynamics (CFD) allows engineers to visualize flow velocity, density, thermal impact, and chemical concentrations for any region where the flow occurs, enabling engineers to analyze the problem areas and suggest the best solutions.

While CFD is used across the construction industry for analysis and design optimization of an HVAC system, some organizations and individuals have been slow to fully utilize it within their practices, citing restrictions such as cost, unreliability, and inaccessibility. In this article, we examine some of the key advantages for its use and assess how current CFD tools are addressing such concerns.

WHY USE CFD?

Engineers designing HVAC systems face an ongoing challenge of meeting sustainability and energy-efficiency targets while still ensuring comfortable, safe environments at a reasonable cost.

Traditional design methods involve the use of hand calculations, which require many simplifying assumptions and ultimately limit the accuracy of calculations.

Incorporating CFD simulation into the design process offers a level of reassurance, allowing a complex design to be tested as a computer model before any construction cost is incurred. Design certainty can be established as scenarios can be accurately simulated with the calculated results graphically displayed in an easily relatable representation.

More and more, engineers are moving to CFD to compute airflow patterns and space temperatures based on complete 3-D geometries with fewer assumptions, resulting in a greater level of accuracy.

One of the most notable advantages of using CFD in HVAC design is the ability to simulate fluid flows and analyze HVAC performance without actually installing the HVAC system or even building a prototype. This allows for significant problems and solutions to be identified and devised to enhance a building's overall HVAC performance.

Due to key advances in HVAC/IAQ technology, broader and more detailed information about the flow within an occupied zone is required, and the CFD technique satisfies this requirement better than any other method (e.g. experimental or theoretical methods).

Increased occupant comfort is a key goal in HVAC, and the finer details of a system, such as location and number of diffusers and exhausts, temperature and flow rate of the supplied air, etc. can be optimized and validated easily with CFD.

Once a design modification has been suggested, these modifications can then undergo further simulation. In addition, any malfunctioning HVAC system can be mitigated for improved performance with better HVAC being the ultimate goal.

Examples of HVAC CFD Analysis in Practice:

- Industrial ventilation design

- Swimming pool ventilation

- General room simulations

- General office and warehouse simulations

- Fume hood design

- Effective smoke evacuation in smoking lounges

- Thermal assessment of data centers and server rooms

- Smoke and fire propagation simulations and implementation of fire safety in occupant structures

CFD is used extensively when designing HVAC systems for non-standard systems, such as stadiums, large atriums, concert halls, natural ventilation systems, smoke ventilation, etc., and most of these systems could not be accurately designed without using CFD.

COMMON MISCONCEPTIONS AND LIMITATIONS

Factors limiting the use of CFD have been lengthy modeling and setup time, expensive software licenses, and extensive training requirements. These challenges are being overcome with a new generation of cloud-based software enabling engineers to access leading-edge CFD capabilities from the cloud on an on-demand basis in a fraction of the time and cost involved in using conventional CFD tools.

Cost: A common misconception held among many HVAC engineers is that CFD is simply too expensive to justify its use, and this relates particularly to the expensive software licenses previously required. Over recent years, many HVAC engineers have vocalized their efforts to find cost-effective, affordable CFD tools, and many software developers have worked to answer these calls.

With the inception of cloud-based, on-demand CFD tools, expensive software licenses are no longer required, and engineers can simply pay for the software as needed. In addition, there are key cost savings to be made when using CFD for HVAC design purposes as physical modifications are hardly required.

Workload Variations: In situations where an engineer's workload is variable, individuals and organizations have questioned the justification of investing in CFD tools. The availability of on-demand, cloud-based CFD software packages has given these engineers the ability to upscale and downscale according to their workload. This also gives engineers the option of including CFD software in their client pitches and paying for what they need if and when they secure the contract.

Confidence, Training, and Time: As with other industries, old habits die hard, and some HVAC engineers have been reluctant to fully embrace CFD into their design practices. For some engineers, having confidence in results with reduced real-world tests has been an issue, and this has also linked in to concerns over user training and knowledge levels. Software developers have focused their efforts on producing code that is most importantly accurate, with the speed-up of simulations very much a secondary factor. Modeling and set-up times have been vastly reduced, and the workflow has been simplified.

There can be no denying that CFD has opened up possibilities in the HVAC arena that were previously not viable, safe, or considerable.

CONCLUSION

There is no doubt that times have changed, and affordable cloud-based tools have changed the way many HVAC engineers view CFD.

CFD tools in the cloud can reduce the time and cost required to achieve thermal comfort, minimize energy consumption, and clear contaminants by providing insights. These insights include predictions of comfort with different design alternatives and quick evaluations of different “what-if” scenarios early in the design process.

Users can now optimize HVAC designs in less time and at a lower cost than was ever possible in the past, so the results of an Aberdeen Group research study come as no surprise, when it found design engineers for best-in-class companies to be 15 percent more likely than the industry average to use CFD to make design trade-off decisions.

With so much to offer, CFD can play a vital role in designing HVAC systems, and, with such clear advantages, it is perhaps now a question of changing perception and overcoming long-held views rather than proving its suitability in this sphere.

For more information, visit www.envenio.ca.

Publication date: 9/4/2017

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment