As I was packing up at a job site recently, carrying several days’ worth of gear back to the truck, a thought struck me. My wife, Maria, and I had, just the night before, been talking with our two young children about what makes us unique and what differentiates us from other animals, including our puppy, Arlo, here on Earth.

So, as I’m hauling stuff to the truck, it occurred to me that what I have in my hands, and what’s on my mind at this very moment, not only helps me define who I am, where I am in life, and what I aspire to be, but also what separates me from all other animals here on planet Earth.

Chief among them are the tools we use and our ability to make (or buy) them, invent new ones, and use them with extraordinary skill. Of course, those who use them well are likely to rise above others, at least to some degree. To do that, we use our God-given minds to experiment with these tools, gradually improve in our abilities, and, eventually, excel.

That sort of plays into the survival-of-the-fittest theme, doesn’t it?

There’s absolutely no doubt we simply could not do what we do as technicians if it wasn’t for the tools we have today. We’re more capable, skilled, and efficient — and we can even work longer hours when we need to — because of the tools we have access to and can put to work. In reality, they make us more powerful.

From cellphones to pipe wrenches, software to hand-held diagnostic devices, and everything in between – our tools are our “force multipliers.” They enable us to do things that no man, woman, or team of pros could do just a generation ago.

Along those lines, I’ve come to regard some of my tools as indispensable. So, in this column, which I’ll offer in two parts, I’d like to discuss some of the tools that have become important to me and my guys while doing the hydronic, HVAC, and plumbing work we do.

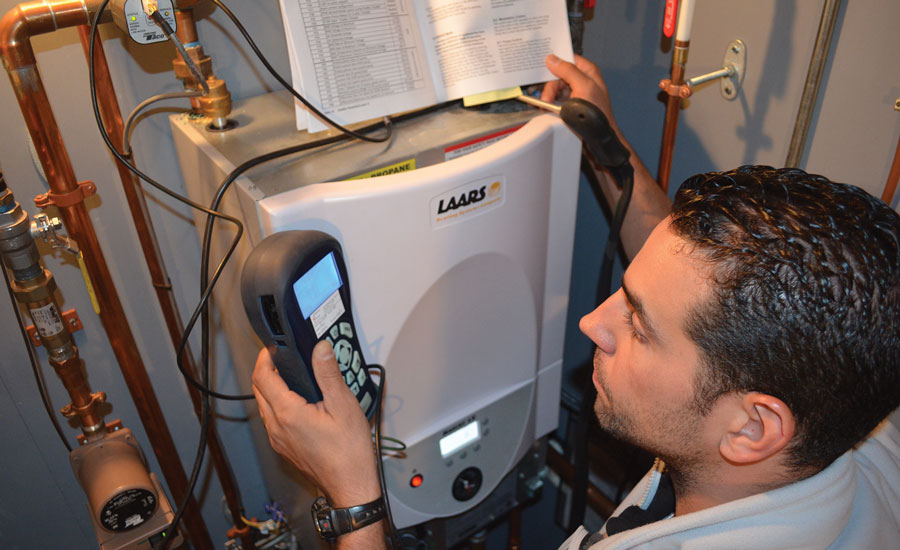

COMBUSTION ANALYZER

Most of us work very hard for our loving families. At the end of the day, there’s nothing more important than returning safely home after a long day of work.

We’re in and out of mechanical rooms on a daily basis. Part of that responsibility is the very real need to protect ourselves and our customers. For that reason, one tool I use daily is my combustion analyzer made by E Instruments Intl. LLC.

The company makes a wide range of combustion analyzers and IAQ measurement tools for residential, commercial, and industrial uses. In my toolbox is the 900 model combustion gas analyzer. These portable, multifunctional combustion gas analyzers are designed to maximize combustion efficiency. They’re also easy to set up to properly service any residential and/or light commercial boilers and burners.

The unit I prefer measures, displays, stores, and prints combustion efficiency, O2, CO, and CO2 as well as all of the necessary temperature, draft, and pressure measurements. Some units are also upgradeable to measure NOx, NO2, and SO2. These combustion gas analyzers also include memory, personal computer (PC) software, and Bluetooth, etc.

I use the tool every time I walk into a mechanical room because the device quickly indicates carbon monoxide levels. In fact, intelligent precaution with this tool happens minutes before entering a mechanical room. When it’s activated outdoors, the device “zeros in” by calibrating the sensor and its microprocessor “brain” by sampling clean air and then quickly comparing it to the air you’ll breathe within the mechanical space.

And, while sampling clean air, this isn’t the time for a quick smoke break.

I use the tool for setting up burners, making sure equipment is running at optimum efficiency, and for liability. It’s an investment that protects us and our customers.

I’ll add that the customer support at E Instruments is really top drawer. Jason Esteves is one of their trainers and product managers. He’s been known to come out to a job site or office to teach techs how to use specific technologies.

Using this tool has been a real eye-opener. The device offers quick, accurate, and reliable combustion analysis — information that not only allows me to fine-tune a furnace, boiler, or water heater, but may someday save my own life or the lives of a customer’s family.

Consider this, too — if you’re the last trade pro to service HVAC equipment at a home or apartment, who do you think will get a call from an attorney if there are deaths from a CO leak?

So, get familiar and friendly with good diagnostic tools. I’ll add that I always opt for their service contract on the unit because I feel it’s always a good investment. These tools must be calibrated yearly, and that’s also when a calibration certificate is provided.

CORDLESS GEAR

I’ve been in the trade now for 15 years. When I was a greenhorn, I saw a need to make a mark. We weren’t exactly peeing on trees to mark our territory, but there was always plenty of showmanship.

I’d eagerly carry eight, 20-foot lengths of schedule 40 polyvinyl chloride (PVC) on my shoulders using straps over uneven terrain. Or, I’d hoist up a cast-iron Kohler tub. Now, I’m a bit more mature and wiser.

The folks at Milwaukee Electric Tool Co. recognize the need for installers to use their minds and bodies more intelligently, too. In fact, I think they’ve helped me slow down the aging process.

I use two of their tools regularly on my jobs: the PVC shear pipe cutter and the copper tubing cutter. Time is money, and if you can get the jobs done in a cleaner and faster manner, it’s a win-win in my book. I like the PVC shear tools because they give my hands a break, and it’s clean; there are no PVC shavings to clean up — and I always try to leave my job sites spotless.

My tool of choice is the M12 2470-21. The cordless PVC shear pipe cutter is great for close quarters work because of the rotating cutting head. Also, there are automatic adjustments to cut tubing from 3/8-inch to 1 inch. There’s an auto-locking mechanism, and it’s ergonomic, too. It’s lightweight and gives 200 +/- cuts per charge.

I use this tool on poly propylene (PPE) and PVC pipe, pex tubing, chlorinated polyvinyl chloride (CPVC), and whatever else a ratchet cutter would handle. I won’t leave home without it.

The tubing cutter — my model is the 2471-21 — is great at cutting copper from ½- to 1 1/8-inch OD, Type K, L, and M. The design offers greater extended reach and reduces wrist strain in hard-to-reach spaces.

This tool really speeds things up, too. At 500 rpm, the cutting mechanism cuts tubing extremely quickly. I use it on installations from potable water to boilers and water heaters.

Incorporated in the head is a handy little LED light that illuminates the pipe you’re cutting; it has a battery indicator, as well.

The tool is user-friendly, but like most, requires a few cuts to get used to. But it’ll auto-calibrate itself on the diameter of the pipe; you just have to hold it steady and centered before pulling the trigger and whaaaaaa-la, you’re off to a speedy install.

Be well, be smart, and use the best tools for the job.

Publication date: 11/21/2016

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment