With the heating season upon us, the search for cracked heat exchangers begins as contractors seek to assure the safety of their customers. As this hunt heats up, is it possible for HVAC contractors to miss other issues that could have much greater impacts on combustion safety? Is it possible to have a combustion safety problem with a heat exchanger that is perfectly intact?

When you perform work on any forced-air HVAC system, the potential exists for airflow to be altered. This can result from something as simple as cleaning a blower wheel or replacing air-handling equipment. As airflow is altered, it can have unintended influences on the safe operation of fuel-fired equipment.

Combustion safety can be sacrificed when fuel-fired appliances needing interior air for combustion are not carefully considered. Many appliances depend on a consistent supply of air from inside the building to operate safely. If this fact is ignored, the results can be deadly.

Let’s look at how unintended airflow changes can influence the safe operation of fuel-fired equipment.

NATURAL AIRFLOW

The buildings we condition are extensions of the HVAC system. An HVAC system is actually a closed-loop system with the connection between the supply registers and return grilles being made by the interior of the building. The walls, floor, and ceiling all make up part of the HVAC system and often have fuel-fired equipment installed inside them.

Natural airflow plays a role in how air moves through the building side of the duct system. This means natural airflow influences the safe operation of natural-draft equipment located in the building. Remembering air movement basics helps us understand the interactions that can occur.

The three biggest influencers are:

1. Hot air rises as cold air falls;

2. Airflow takes the path of least resistance; and

3. 1 cfm in = 1 cfm out.

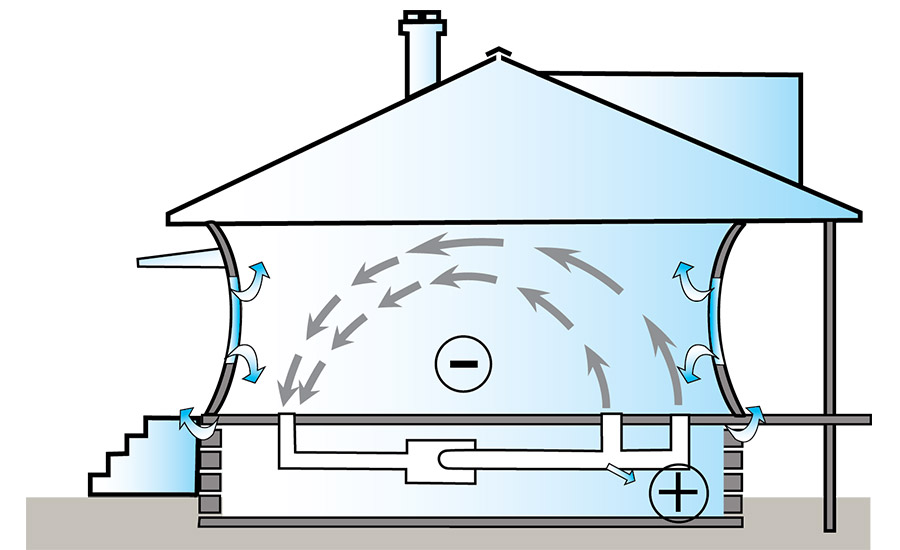

A phenomenon known as the stack effect uses all three of these airflow influences to unintentionally turn a building into a competing flue if conditions are right. This condition is more noticeable in taller buildings during the heating season.

As heated indoor air escapes outside through a wide variety of leakage sites found in the typical home, air is brought in to replace it.

Unfortunately, one of the sources commonly used to replenish exhausted air is the flue itself. Stack effect unintentionally turns a combustion gas exhaust pipe into a makeup air duct. This is one of the most overlooked and misdiagnosed problems contributing to combustion safety issues. The result can be illness or death to building occupants.

HVAC SYSTEM AIRFLOW

In addition to the impact of natural airflow, the blower of an HVAC system can be an even stronger influence; in fact, it can be 50-times stronger than stack effect. When unbalanced airflow exists in a duct system, the path of least resistance rules.

Duct leakage plays a significant role in combustion safety issues of fuel-fired equipment. Return duct leakage inside a building allows air designed for certain rooms to short circuit or bypass its intended destination. Supply duct leaks located outside the conditioned areas of a building act in a similar manner.

When such leakage is present, the potential for pressure imbalances are created. Imbalances can lead to intermittent periods of flue gas spillage when the fan is operating. Imagine what could potentially happen if duct leakage exists and you install a two-stage furnace or advise your customers to run the fan in the on position. The outcome could be less than desirable.

Duct leakage isn’t the only influence from HVAC system airflow to be considered. The absence of air balancing is another way the fan from the HVAC system can influence combustion safety. Just as duct leakage causes air to short circuit its intended destination, failing to air balance a system can have similar results. When measured airflow of supplies and returns is assumed, it can unknowingly result in a competition for combustion air.

Even on a perfect duct system, the building itself can influence HVAC system airflow. Interior doors often act as conditioned space manual dampers — just like dampers in a branch duct. Simply closing an interior door can unintentionally shut-off airflow from one room to another. This is commonly encountered on systems with a central return grille.

EXHAUST FAN AIRFLOW

In addition to the blower in the HVAC system, exhaust fans can play havoc on airflow. Any fan exhausting air from inside the building needs to be considered here. These include kitchen exhaust fans, clothes dryers, radon mitigation systems, and bath fans — all common influencers to be aware of.

The higher the volume of air moved outside by an exhaust fan, the more likely that fan is to create a problem. The combination of a small mechanical room and clothes dryer has often been the source of water heater backdrafting.

PREVENTING UNINTENDED AIRFLOW INFLUENCES

Awareness and understanding is important in preventing these unintended influences from occurring. There are solutions to each problem. Measurements must be taken to uncover the problems, as guessing just doesn’t cut it. Begin by learning the principles of airflow and combustion, so you understand how they influence the HVAC systems you encounter daily.

If you suspect airflow issues could cause equipment to operate unsafely, test to assure safe operation both before and after any changes have been made. With the right test instruments and procedures, a properly trained technician can predict and resolve any unintended airflow influences.

To read more Duct Dynasty articles, visit Bit.ly/DuctDynasty.

Publication date: 11/7/2016

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment