Smaller refrigeration compressors, usually under 3 horsepower, typically have splash-type lubrication systems without an oil pump. These compressors often have an oil scoop that flings oil throughout the compressor’s crankcase, causing an oil fog that lubricates the bearings, wrist pins, pistons, and rings.

However, larger compressors will have forced lubrication oiling systems. These compressors contain an oil pump located at the end of the compressor’s crankshaft. This oil pump is driven directly by the compressor’s crankshaft and rotates at the same RPMs as the compressor. The oil is forced under pressure through holes or oil galleys drilled in the crankshaft, piston rods, wristpins, and supporting bearing structures and surfaces. The oil then drops to the crankcase to again be picked up by the suction of the oil pump. Often, the oil is filtered by a fine mesh screen and then enters the suction of the oil pump to be pressurized and start the process over again.

Many compressors have a partition wall that separates the crankcase from the motor barrel. On refrigerant gas-cooled compressors, the motor barrel is where the motor windings and stator reside, and where oil-entrained suction gases enter the compressor’s end bell through the suction service valve. Because the motor barrel has a large diameter compared to the suction line, oil-entrained suction gases will lose velocity and slow down significantly as they enter the motor barrel. This loss of velocity of the oil-entrained suction gases will cause the oil in the suction gases to drop out and collect at the bottom of the motor barrel.

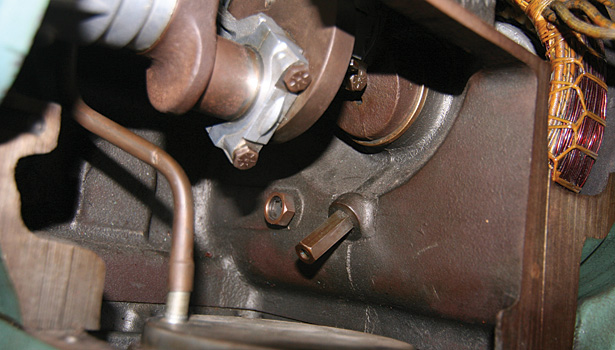

The partition wall that separates the motor barrel from the compressor’s crankcase has an oil check valve, which will only let oil pass from the compressor’s motor barrel to its crankcase. When the compressor is running and no system problems exist, there is usually a 1-2 psi pressure drop from the motor barrel and the crankcase. This pressure difference allows the oil check valve to be open, which allows any collected oil in the bottom of the motor barrel to return to the compressor’s crankcase. The returned oil can now be picked up by the oil pump and delivered throughout the compressor’s moving parts to provide lubrication.

However, during startup periods or when some system problems occur, the compressor’s crankcase could experience a slightly higher pressure than the motor barrel. It is in these cases where the oil check valve will be closed, thus preventing any oil return to the crankcase for use by the oil pump. An accumulation of oil will now occur in the motor barrel, which will prevent the compressor’s crankcase from receiving any new oil from the motor barrel. If the system problem is not cleared up or remedied soon after startup, the oil check valve will remain closed and the crankcase will soon be starved of oil, causing loss of lubrication and a tripping of the oil safety control.

Coping With Challenges

Some system problems that may cause this situation are:

• Liquid refrigerant floodback during the on cycle from the motor barrel to the crankcase;

• Compressor startups with liquid refrigerant in the crankcase;

• Refrigerant migration to the crankcase from the suction line and motor barrel during the off cycle, causing startup pressurization of the crankcase. Refrigerant loves oil and will migrate to it because of the oil’s lower vapor pressure;

• No automatic pump-down system to prevent refrigerant migration; and

• Compressor located outside in a cold ambient, causing refrigerant migration during the off cycle from suction line through the motor barrel to the crankcase. This causes oil foaming and crankcase pressurization at startups.

Publication date: 6/2/2014

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment