Counterfeit R-134a, containing R-40 (methyl chloride or chloromethane), has been found in mobile air conditioners, stationary air conditioning, and transport refrigeration systems in many countries. For your personal safety and to avoid serious injury or death, special care must be taken when accessing the service ports to sample or work on systems that are not functioning properly or have been serviced by others. R-40 chemically reacts with aluminum inside HVACR systems, generating highly reactive and/or toxic compounds, and exposure of the system’s contents to air and/or moisture could result in production of a strong acid and violent chemical reaction. Several container systems have exploded at service facilities, some resulting in fatalities. Some of these systems were found to contain R-40 and/or other unacceptable substances.

Compounds such as R-40, R-22, R-142b, R-152a, and R-12 have been found mixed with R-134a in newly filled refrigerant cylinders marked as containing R-134a. There have also been instances of counterfeited brand-name R-134a cylinders sold containing refrigerants other than R-134a.

Research is being conducted by ASHRAE to identify the reaction mechanisms for R-40 and aluminum inside systems, as well as other reaction products. It is also necessary to determine the concentration of R-40 that is safe as a contaminant. AHRI Standard 700-2012, Specification for Fluorocarbon Refrigerants, would allow up to 0.5 percent of other volatile impurities. There have been no known issues arising from refrigerant that meets AHRI Standard 700.

Unfortunately, the problem with counterfeit and contaminated refrigerants goes beyond just R-134a. Other refrigerants, including R-22, R-404A, and R-410A, have also been found to be counterfeit and in some instances badly contaminated. Cylinder labels and packaging have been counterfeited in some instances, and therefore are not reliable indicators of the authenticity of the contents of a cylinder. Contaminated refrigerants can cause a variety of issues that may range from increasing energy use and decreasing cooling performance, to significantly reducing the operating life of equipment, and even dramatic and injurious equipment failures, as in the case of R-40 contamination. In addition, some counterfeit refrigerant products contain varying amounts of ozone-depleting substances, which may be illegal in certain parts of the world under the terms of the Montreal Protocol.

It is good practice to purchase refrigerants from reputable, reliable sources. Failure to do so could result in the purchase of counterfeit refrigerants that contain substances such as R-40.

Steps to Avoid Counterfeit Refrigerants

• Know your supplier. Obtaining refrigerant from a trusted and well-known source that can provide traceability is good practice to prevent contamination of an HVACR system.

• Verify the refrigerant in the cylinder before using. Proper verification of refrigerant in service cylinders prior to use can ensure authenticity of the refrigerant. Checking refrigerant cylinders in the field with a portable refrigerant analyzer or performing a halide torch test can also help prevent contamination.

• Verify refrigerant in the system before repairing/servicing. Proper verification of refrigerant identity and impurity profile in the refrigeration systems prior to repairing and/or servicing the system is a good industrial practice and imperative to safety. Testing refrigerant in systems prior to removing the charge can also prevent possible contamination of recovery equipment and recovery cylinders.

• Properly label and isolate contaminated refrigeration systems. Properly label all suspected contaminated refrigeration systems to ensure that systems containing contaminated refrigerants are quarantined until they can be dealt with properly, as discussed below in the remediation section.

Methods to Detect R-40 and Other Contaminants

While there are no known portable refrigerant analyzers produced prior to 2012 with any capability to detect R-40, several models were introduced in 2012 with the capability to detect R-40 quantities as low as 2-3 percent. These devices also have the capability to detect other contaminants, including CFCs and hydrocarbons. Halide torch testing has the capability to detect chlorinated compounds as low as 300 parts per million (ppm); however the method is not capable of detecting other contaminants, such as hydrocarbons. Using a combination of the two methods provides the widest range of contaminant detection available in a field test. A pressure-temperature relationship (PT) check is not a recommended procedure to determine if a refrigerant cylinder is contaminated, as a contaminated system that contains a refrigerant blend could indicate pressures similar to those of pure R-12 or R-134a.

Portable Infrared Analyzer

|

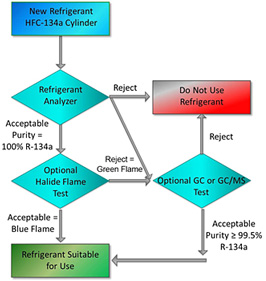

| Figure 1. The flow chart is a process for determining if new R-134a supply containers might contain significant amounts of refrigerant contaminants. |

The flow chart (Figure 1) shows a process for determining if new R-134a supply containers might contain significant amounts of other refrigerant contaminants. This flow chart may not be suitable for use with refrigerant recovered from a system. The new refrigerant container is first analyzed in the field with an R-40-capable portable infrared analyzer. If the results show 100 percent R-134a with no other contaminants present, the refrigerant should be suitable for use in systems. If the portable analyzer shows a test result other than 100 percent R-134a, the refrigerant should be quarantined and not used unless further testing shows that the contaminants are below the maximum level recommended by AHRI Standard 700.

Halide Torch Testing

If further field testing to confirm the specific presence of chlorinated impurities is desirable, the optional halide torch testing method may be performed. If the flame in the torch does not turn a greenish color when the refrigerant sample is introduced, the level of chlorinated compounds is less than several hundred parts per million and the refrigerant is likely suitable for use in systems. A green flame indicates the presence of chlorinated impurities, but these impurities may be acceptable if they have low toxicity and low reactivity in systems, or unacceptable if they are highly reactive or toxic like R-40. Care must be exercised when performing the halide torch test to ensure that the gas flow is optimal for a flame color reading.

Gas Chromatography or GC/Mass Spectrometer Testing

When laboratory testing is deemed necessary to determine the specific identity of the impurities in the refrigerant container, optional gas chromatography (GC) or GC/mass spectrometer (MS) testing may be performed. The tests give detailed information on the composition of the refrigerant and impurities present. If the refrigerant meets the purity requirements of AHRI 700, the refrigerant should be suitable for use in systems.

It is important to be familiar with the operation and instruction manual for all equipment used when testing refrigerants. This is particularly important when using this equipment to detect R-40 contamination.

Remediation of Systems Contaminated with R-40

At-risk HVACR systems (systems suspected or confirmed of containing refrigerant contaminated with R-40) may also contain compounds formed from the reaction of R-40 with system components. Some of the possible reaction compounds are pyrophoric compounds formed from the reaction of R-40 with aluminum components in the system, and can react violently when exposed to air and/or moisture.

Any at-risk HVACR system should be immediately powered down and isolated to minimize the risk of explosion from exposure of the contaminated refrigerant to air or water and to eliminate any potential ignition source. No remediation should be attempted until the contaminated refrigerant in the at-risk HVACR system can be safely neutralized and removed. At the present time, there are no accepted industry practices or procedures for safely remediating an at-risk HVACR system. Some of the key elements needed in a remediation procedure are:

• A sampling procedure for collecting contaminated refrigerant in the container without exposure to air or moisture;

• In situ neutralization procedure for neutralizing potential pyrophoric reaction compounds in the system prior to removal of the contaminated refrigerant from the system;

• Recovery/disposal procedure to safely remove and dispose of neutralized contaminated refrigerant and reaction compounds from the system; and

• A procedure for assessment of system integrity and remediation work required to return the HVACR system to service.

Various industry groups are working on development for all of the procedures listed above, but no industry-accepted remediation procedure has been validated. The sampling, neutralization, and recovery/disposal procedures will be required for safe removal and disposal of the contaminated refrigerant from the system, regardless of whether or not the at-risk HVACR system can be adequately remediated and returned to service.

Maximum Acceptable Levels of R-40

AHRI Standard 700-2012 states that refrigerant impurities may be present at 0.5 percent, or 5,000 ppm or less, in any pure refrigerant or refrigerant blend. Therefore, the maximum level of R-40 that could be found in virgin refrigerant, while very unlikely, could be up to 5,000 ppm. AHRI recently conducted a survey of several chemical manufacturers and found that typical R-40 levels in virgin refrigerant from reputable sources were less than 100 ppm. There have been no known issues arising from the presence of R-40 impurity in virgin refrigerant, i.e., refrigerant that meets or exceeds the requirements of AHRI Standard 700.

Publication date: 12/9/2013

Report Abusive Comment