|

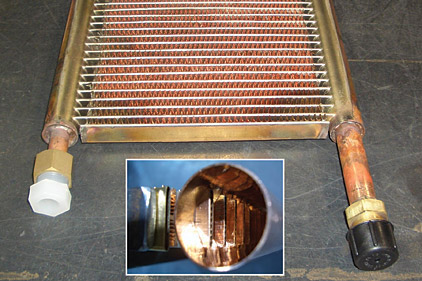

| All-copper brazed heat exchanger with thin-wall multichannel coils. (Photo courtesy of Russ College of Engineering and Technology at Ohio University) |

Those small-diameter coils — with names like MicroGroove, microchannel, and micro-multichannel — have gained a beachhead in residential heating and air conditioning, and are advancing in commercial HVAC, with refrigeration on the horizon.

The refrigeration destination may, more often than not, currently be in the computer-modeling stage but real-world applications are starting to arrive. It is just a matter of completing the fine-tuning on the a/c side before venturing into refrigeration equipment to an even greater extent.

“There is a potential in refrigeration, especially with such low refrigerant charges, for these coils to work with some of the newer refrigerants like propane and CO2,” said Matt Holland, vice president of operations for Super Radiator Coils, which sells coils made with MicroGroove copper tubes.

“This is a specialized refrigeration equipment market,” said Frank Kraft, referencing the copper microchannel tubing he helped develop. Kraft, associate professor and director of the center for advanced materials processing in the mechanical engineering department of Ohio University’s Russ college of engineering and technology in Athens, Ohio, added, “Even though the economy fluctuates, people need medicine and they still need to eat, so there is a fairly stable revenue stream available for related residential and commercial refrigeration equipment.”

Trending Up

The freshness of the technology is adding to the still-early foray into refrigeration. As recently as the International Air-Conditioning, Heating, Refrigerating Exposition this past January in Dallas, the International Copper Association (ICA) was calling upon tube suppliers, equipment makers, and heat exchanger manufacturers to share expertise on topics relating to smaller-diameter copper tubes at the new product and technology theatre.

“MicroGroove technology, originally developed for room air conditioners including window units and split systems, is now also recognized by manufacturers as being well suited for large heat exchangers in commercial-sized air conditioning and refrigeration systems,” said Nigel Cotton, microGroove global team leader for the ICA. “When smaller-diameter copper tubes are used in the construction of large-area heat exchanger coils, major advantages are realized in terms of energy savings, materials savings, reduced refrigerant charge, and smaller footprints.”

With the MicroGroove development comes heat-exchange simulation software for refrigeration that was developed by ICA and Shanghai Jiao Tong University.

According to Kerry Song, ICA Asia project manager, who served as one of the developers of the technology in China, it was “designed to assist the users to choose MicroGroove copper tubes in the fin-and-tube heat exchanger design for refrigeration and simulate the performance with different path.”

Song presented a report on the small-diameter tubing as recently as the 2012 concurrent HVACR conferences at Purdue University in West Lafayette, Ind.

Micro-multichannel

The approach being developed by Ohio University is called “micro-multichannel,” according to Barbara Varone, technology commercialization manager at the innovation center at Ohio University. “Microchannel heat exchangers are the latest trend in heating and cooling technologies, providing up to a 40 percent increase in efficiency,” she said.

An example of the potential is reflected in comments from Ohio University’s Kraft. “Since 2007, the ICA has been working with Ohio University to develop flat, multi-channel tubes made from copper and/or copper alloys. Such a product provides excellent thermal conductivity and a high surface-area-to-volume ratio that enables the development of high-performance and energy-efficient heat exchangers for heating and cooling, including applications in electronics cooling, solar-energy conversion, and solid-state laser cooling.”

Aluminum Advances

Advances for microchannel aluminum coils in refrigeration are also underway. Andrea Knapp, media relations manager for Delphi, said, “Delphi’s MCHX evaporator and condenser both have refrigeration applications. Using microchannel technology, our systems are compact, efficient, and help OEMs meet upcoming SEER requirements.”

The company noted, “Offering more-efficient heating and cooling through microchannel technology, Delphi’s MCHX outdoor heat pump coil is changing the way air conditioning/refrigeration manufacturers think about heating and cooling.

“By extending our proven micro-channel technology to the outdoor heat pump coil, we can help our customers as well as consumers save energy, space, and costs, while reducing impact on the environment and gaining in overall system performance,” said Chris Day, global product line director for Delphi.

The coil is based on Delphi’s patented microchannel heat exchanger technology. The brazed aluminum system joins key components — a flat microchannel tube, the fins, and two refrigerant manifolds — together in a single coil. “The optimized coil design provides a high rate of heat transfer while maintaining low air-side pressure drop,” Day said.

Publication date: 6/10/2013

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment