|

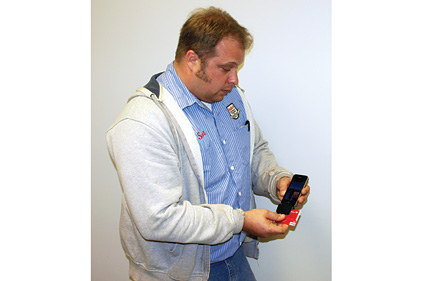

| Service technician Scott Pires, Welsch Heating & Cooling Co., accepts a customer’s credit card payment on his iPhone. Welsch’s has recently moved to smartphones for its techs and began accepting credit card payments on-site through them. |

For a company that’s been in business 118 years, making upgrades isn’t an option, it’s a necessity. That’s why Butch Welsch, president of Welsch Heating & Cooling Co., St. Louis, always makes sure to stick to one key principle despite the rapidly changing times we live in: First impressions are everything.

Welsch makes sure his company is always equipped with the right technology — whether it’s tools, computers, phones, transportation, or even how they take credit cards — to make their first meeting with a customer as welcoming as possible.

If something isn’t working, or if he feels his team is falling behind, Welsch said he isn’t afraid to reinvest into the company, especially if he feels it will help increase productivity.

“We’re not a very impulsive company,” he admitted. “I’ve always been one to think about a decision, sleep on it overnight, and then decide if it’s really the right one. So, we might take a little longer in the exploratory stage than some, but we want our decisions to last. We’re looking to make long-term deals. We don’t go into things thinking it’s only going to last a couple of years. We aim for at least five years with each decision we make.”

Some of Welsch’s recent business acquisitions include a plasma cutter and a newly integrated computer system.

Most recently, he replaced the company’s line of Nextel Push-to-Talk phones, which he’d had offered since 1999, to iPhone and Android devices. The technology upgrade has allowed him to receive service technician updates and schedules via text message. His team also utilizes the Square® program to directly swipe and verify a customer’s credit card information. He’s also equipped his sales team with iPads, which include complete manufacturer catalogues, and offers technicians the ability to electronically prepare a quote on the spot.

“That’s been very popular,” he said. “Customers have been very impressed with this.”

On top of that, he makes sure his company’s fleet of around 50 pick-up and delivery trucks is well maintained and evaluated.

“We’ll typically rotate seven to eight per year, depending on their mileage and their usage to determine which ones get replaced,” Welsch said. “Our intention is for about one-eighth of our fleet to be replaced each year. I don’t think you can have a service truck go out on a call that looks like you’re some back-alley operation or something. That just doesn’t cut it. We’re professionals and we need to look and act like it.”

Welsch isn’t just investing into material items, he’s investing into his employees as well, with continued technical and soft-skills instruction.

“We do training with our service techs. Outside of technical skills, we focus on a number of other things, such as where and how to park the truck, how to approach the door, customer introductions, how to share a business card, and more. We make sure they’re comfortable and have a presentable-looking truck. All those things are absolutely key to establishing a welcoming first impression,” he said.

Approximately 20 years ago, Welsch said he decided to make a major shift in the way his company operates. He now recognizes this as the most influential decision he’s ever made.

“We were strictly a new construction or new residential contractor, but, starting in 1990, we started changing the focus of the company to the point that we’re at today. Now, we’re 60 percent service and replacement and 40 percent new construction,” he said.

Welsch isn’t the only contractor banking on business alterations.

Terry Roden, president of Teco Metal Products, Dallas, said he plans to reinvest at least $4 million into his company through the next seven years.

Teco recently moved from an 85,000-square-foot building to a new 110,000-square-foot facility about a half-mile away.

“We shopped for buildings to see what was available, and ironically we found a building about a half-mile from where we were. They made a wonderful offer and we closed on a fantastic price,” Roden said. “The building I was in was kind of cut up, so the flow was never really good; now I’m in one large space with more than 100,000 square feet. It’s really a massive space.”

Even though his lease on the original building isn’t up until October, Roden said he’ll gladly carry both buildings until then because of the increased productivity.

“We moved on Dec. 6 and increased production at least 15 percent right away, just because of the flow,” he said.

Roden said his latest additions include a 250-ton press brake, with plans to add another later this year, and a $720,000 fiberoptic laser, due to arrive any day.

“I’m banking on 10 years of growth,” he said. “We’ve shown growth in every year since 1997. Some years were really marginal, but it’s been growth.”

For Air Conditioning Contractors of America (ACCA) president and CEO Paul Stalknecht, continuing education is one of the greatest investments a company can make.

“This is an area where the most successful contracting businesses are staying ahead of the competition, by providing regular technician education in new systems and services,” he said. “We tell homeowners, if you want to know something about a contractor, ask him to explain his continuing education program. If he can’t answer that question enthusiastically, then you probably shouldn’t hire him.

“The nature of this industry is such that you cannot achieve continued success based on simply obtaining a degree or certification, or completing an apprenticeship program. Those are all important and necessary building blocks, but education cannot, and should not, stop once you get certified. The new kinds of technology entering this field require a new level of sophisticated knowledge, and contractors need to make sure their employees have that knowledge.”

Publication date: 3/25/2013

Report Abusive Comment