The amount of evaporator superheat that is required for a certain application will vary. Some commercial icemakers call for 3-5 degrees of evaporator superheat to fill out their ice sheets.

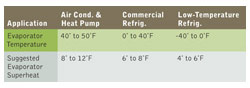

The amount of evaporator superheat that is required for a certain application will vary. Some commercial icemakers call for 3-5 degrees of evaporator superheat to fill out their ice sheets.However, suction line accumulators are often employed on these systems for added protection. This will help ensure that all refrigerant entering the compressor is liquid free. This will also help keep a fully active evaporator. Lower temperature applications generally utilize lower evaporator superheats than medium- and high-temperature applications. Please consult the case and/or appliance manufacturer if in doubt. (In the absence of manufacturer’s data, the chart on page 17 shows guidelines for evaporator superheat settings.)

There will always be a time when the evaporator sees a light load and the TXV may lose control of its evaporator superheat due to limitations of the valve and to system instability. This is where total superheat comes into play.

Total Superheat

Total superheat is all the superheat in the low side of the refrigeration system. It starts at the 100 percent saturated vapor point in the evaporator and ends at the compressor inlet. It is sometimes referred to as compressor superheat. Total superheat consists of evaporator superheat plus suction line superheat. A technician can measure total superheat by placing a thermistor or thermocouple at the compressor’s inlet and taking the temperature. A pressure reading will also be needed at this same location.

Example: HFC-134a system with low side pressure at compressor of 20 psig or 23˚F. (Refer to a R-134a pressure/temperature relationship chart). The compressor inlet temperature = 50˚.

Here’s the total superheat calculation: 50˚ compressor in temperature – 23˚ saturation temperature = 27˚ total superheat.

In the example, the total superheat was calculated to be 27˚. It is possible to have a TXV that is adjusted to control superheat at the coil (evaporator superheat) and still return liquid refrigerant to the compressor at certain low load conditions. If so, the conditions causing the floodback should be found and corrected. It is recommended that all TXV controlled refrigeration systems have some compressor superheat to ensure that the compressor will not see liquid refrigerant flood or slug at low evaporator loads. The TXV, however, should be set to maintain proper superheat for the evaporator, not for the compressor.

Air-cooled compressors are more vulnerable to slugging and valve damage because the returning suction line gases are not heated by the motor windings. The gases enter the sidewall of the compressor and go directly to the valves. Compressor or total superheat will be a buffer in case the TXV loses control of superheat at these low loads. (However, the evaporator superheat must still be maintained by the guidelines in the chart.)

A buffer of compressor superheat will also make sure that the refrigerant vapor entering the compressor is not too dense. Too high of density vapors entering the compressor will cause the compressor to have a higher than normal amp draw. This will overload the compressor in many instances and open thermal overloads. On the other hand, excess suction gas superheat and/or long periods of low mass flow rate (e.g., an unloaded compressor or variable capacity compressor at lower capacities) can result in insufficient cooling of the rotor, motor, and stator and open the internal protectors.

Always consult the compressor manufacturer for the maximum return gas temperature the compressor can handle to prevent compressor overheating. Many appliance and refrigerated case manufacturers are working with compressor manufacturers to determine the optimum amount of compressor superheat so as not to overheat compressors. The proper amount of compressor superheat will ensure a cool running compressor and at the same time ensure the proper density suction gases for good capacities.

Remember, the TXV controls evaporator superheat. To obtain more total superheat, one may add a liquid/suction heat exchanger, or even run a bit longer suction line to allow heat gains from the surrounding temperature to heat the suction line.

It is not recommended to take the insulation off of the suction line to increase total superheat. This will cause the suction line to sweat from water vapor in the air reaching its dewpoint on the suction line. Freezing of this condensation may also occur if suction line temperatures are below 32˚. Water damage can occur. If at all possible, do not sacrifice (raise) evaporator superheat to get the amount of total superheat needed. This will not maintain an active evaporator and system capacity will suffer.

TXVs often lose control of evaporator superheat at evaporator loads. Low evaporator loads can be caused from many different situations. The following are some causes for low load conditions on evaporator coils:

• Evaporator fan motor not operating

• Iced up or dirty coil

• Dirty filter before evaporator

• Defrost circuit malfunction causing coil icing

• End of the refrigeration cycle

• Low air flow across evaporator coil

• Low on refrigerant charge

Any time the evaporator coil sees a reduced heat load than that it is designed to see, a TXV can lose control and hunt. Hunting is nothing but the valve overfeeding and then underfeeding trying to find itself. Hunting occurs during periods of system unbalance (e.g. low loads) when temperatures and pressures become unstable. The TXV tends to overfeed and underfeed in response to these rapidly changing values until the system conditions settle out, and the TXV can stabilize. It is this overfeeding condition that hurts compressors. Too low evaporator superheat setting also causes the TXV to hunt.

Publication date: 12/3/2012

Report Abusive Comment