|

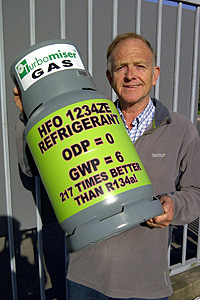

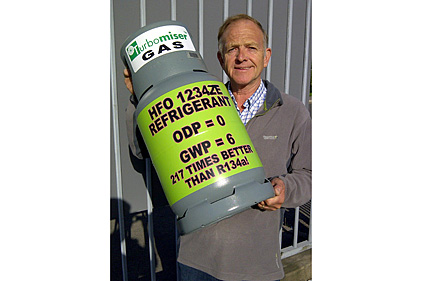

| Ken Strong, managing director of Cool-Therm Ltd., shows a canister of HFO-1234ze being used in chillers. |

CO2

With CO2 as a refrigerant gaining greater attention, the question becomes when will it gain widespread application. To determine how far the refrigerant has come in terms of user acceptance — and how far it has to go — Danfoss conducted what it called a “preliminary industry indicator” in the summer of 2012 targeting OEMs, consultants, contractors, and end users, drawing from its existing food retail and industrial refrigeration customers.

In all, there were close to 1,000 surveys emailed out with a response of 15 percent.

When asked if they believe CO2 is “a viable alternative refrigerant,” 84 percent of the OEMs surveyed said yes, and 16 percent said no. That itself could bode well for continued development of applications for its use. At the same time, when asked what percentage of their business do they expect to be using CO2 in the next five years, 68 percent said less than 10 percent while 16 percent of those responding said more than 20 percent.

The consultants and end users were asked if they had done any projects with CO2 and 31 percent said yes, while 69 percent said no. Of those working on CO2 projects, 58 percent of them were primarily transcritical, while 42 percent were subcritical. When CO2 was first introduced to the refrigeration sector on a wide basis less than a decade ago, first attention was given to subcritical as the less challenging of the two approaches. But more and more transcritical equipment has been coming on the market.

Another statistic for wider application came when the consultants and end users were asked, “Are your CO2 projects mainly new construction or retrofits?” While 78 percent said ‘new,’ 22 percent said the refrigerant is being used in retrofit applications.

Those surveyed were asked about motivators behind using CO2. “Pending legislation/regulation” of familiar f-gases was seen as a driver by 38 percent of those responding, while at the same time 38 percent also found “energy efficiency/demand response capabilities” to also be positive. In effect this says that should f-gases face regulated phasedowns, CO2 could work without sacrificing energy efficiencies.

When asked about barriers to implementing CO2, the two most common were related to initial costs and contractors not being familiar with system design — both of which can be overcome as more installations come on-line. In addition, some 38 percent of those responding to the question raised concerns about systems using CO2 being high-pressure systems.

Another element of the learning curve relates to materials available in order to specify CO2 projects. When the question was asked of consultants, 63 percent said there is not yet adequate information available to accurately specify projects, while at the same time 37 percent said there was enough to specify CO2 projects.

In terms of contractors, 27 percent of those responding said they’ve worked with CO2 systems. But the findings also indicated that there is a strong need for education and training regarding CO2 systems and their requirements.

Like their consultant and end user counterparts, contractors saw pending legislation/regulations and favorable energy efficiencies as positives for CO2 systems, while lack of familiarity with such systems is the primary negative currently.

HFOs

In another non-f-gas development, the United Kingdom website heatingandventilating.net posted on Oct. 9, 2012, that “Honeywell has collaborated with Haier Group to introduce what it claims is the world’s first HFO refrigerant air conditioner.

“The demonstration unit, previewed at the Chillventa show in Nuremberg, Germany, contains Honeywell’s new HFO blend refrigerant, Solstice L-41,” the site said.

“The unit is the first produced by the Haier Network Smart Appliance Project, a cooperative effort between Honeywell’s Shanghai R&D center and the Haier National Laboratory.”

The news item went on to note that the HFO has an ASHRAE A2L rating.

Also, the British company Cool-Therm Ltd. said it has developed a new generation of Turbomiser chillers based on HFO refrigerants.

The company said it believes that the chillers, which run on HFO1234ze, offer the best solution to the industry’s twin requirement for improved energy efficiency and reduced environmental impact.

Ken Strong, managing director, said, “HFO1234ze has a global warming potential of just 6 compared with 1,300 for the common HFC refrigerant R-134a. It is effectively 217 times less damaging than today’s mainstream refrigerant, making it much more environmentally responsible.”

He added, “When coupled with the inherent energy efficiency of Turbomiser, it offers industry and end users a proven solution, delivering reduced carbon emissions, lower running costs, and safeguarding the environment.”

Publication date: 11/26/2012

Report Abusive Comment