Now, Bob’s company has promoted him to help train a new employee, right out of a school specializing in HVAC, just like Bob was. Bob is now Tim’s Btu Buddy. Tim is anxious to travel with Bob. Tim realizes that he is right out of school, with the theory and lab work that he accomplished in school, but still needs help. He knows that he worked with many of the components of the systems in the school, under ideal conditions with good light and air conditioning. Now it is into the field, sometimes under the house with poor lighting, or out on the rooftop in the sun, where the real action is. He is naturally and normally reluctant, but he has Bob to help guide him.

Bob and Tim have been sent on a call to a house with no cooling. The system has just been installed and the construction crew has been having problems with startup.

When they arrived, the construction foreman explained, “The unit began to freeze up shortly after startup so I put gauges on the unit. The suction pressure was very low, so I added refrigerant. The suction pressure only rose a little, and the head pressure went up quickly. I stopped adding refrigerant and called the office.”

Bob and Tim took it from there. Bob said, “The system has a capillary tube metering device. Let’s look at what may be wrong. Start the unit and let it run for 10 minutes while we look over the system.”

After about 10 minutes, Bob said to Tim, “Write these numbers down. We know that:

1. The refrigerant is R-410A.

2. The return air temperature is 85°F because the inside of the house is hot and the unit has not been running.

3. The outside ambient is 95°.

4. The metering device is a capillary tube.

5. The suction pressure is 75 psig, corresponding to 18°.

6. The head pressure is 506 psig, corresponding to 135°.

7. The head pressure should be about 445.8 psig, corresponding to 125° (95° + 30° = 125°).”

Bob asked Tim, “What do you see in these numbers?”

Tim said, “It is just like the construction foreman said, there is plenty of load on the unit and it is still freezing up. He added refrigerant and something is not right because the suction pressure is still well below freezing and the head pressure is too high. I think that now it has too much refrigerant in the system.”

Bob asked, “What do you think we should do next?”

Tim said, “You are asking me some hard questions, but I think there must be a restriction somewhere. How do we find it?”

Bob said, “Let’s do a touch test of the liquid line and see what we can find.”

|

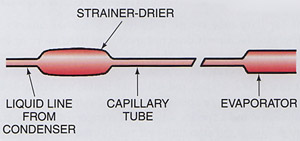

| Figure 1. This is a one circuit example of a capillary tube connected to a strainer-drier. (From Refrigeration & Air Conditioning Technology, seventh edition, by William Whitman, William Johnson, John Tomczyk, and Eugene Silberstein, published by Delmar Cengage Learning.) (©Delmar Cengage Learning.) |

They started at the condensing unit and felt the liquid line all the way to the strainer-drier just before the capillary tubes. All seemed normal.

Bob said, “I believe the restriction is either in the strainer-drier or in the capillary tube system. Let’s recover the refrigerant and remove the strainer-drier. Then we can see if we can push nitrogen through it. If it seems as though it is not restricted, we will then remove the capillary tube system and change them both.”

Tim then asked, “Why not just remove the capillary tube system and the strainer-drier and change them both?”

Bob said, “There are actually four circuits which each have a capillary tube feeding it. If we can just change the strainer-drier, we will have a much easier repair. We will not have to deal with all of the silver brazing by removing the four circuits from the coil and then re-silver brazing them. At that point, I believe we would ask for a new coil and change it.”

They recovered the refrigerant and evacuated the system and raised the system pressure to 0 psig with nitrogen and removed the strainer-drier.

Bob said, “Take the nitrogen hose and nozzle and see how much nitrogen will blow through the strainer-drier. Use about 100 psig of pressure.”

Tim tried it and said, “Not very much is coming out.”

Bob then said, “Now try blowing it backwards. Put the hose in the outlet of the strainer-drier. Use this clean white handkerchief to see if you catch anything.”

Tim did it and said, “Wow, some trash came out and I caught it in the handkerchief. It seems as though more will flow now.”

Bob said, “You have found the problem. That is trash from when the unit was assembled at the factory. Use your cell phone and take a picture of the trash. Someone was careless. When we write the service report we will spell out what happened and include the photo. When our company bills the manufacturer for our time, they will be able to trace this problem right to the source in the factory. You have the evidence to show. Also, save the strainer-drier. They may also want to see it.”

They changed the strainer-drier, evacuated the system, and charged the unit with fresh refrigerant by weighing in the charge and started it up.

Tim looked at the gauges and said, “That was a really interesting set of circumstances. Things are different every day it seems like. I think I like that.”

Bob added, “In this business of troubleshooting, the education never ends. I like that because not just everybody will take the time to learn this business. That means that the opportunity and income keeps going up.”

Publication date: 8/20/2012

Report Abusive Comment