|

| Figure 1. Severely oil-logged evaporator |

Refrigerant migration deals with refrigerant migrating back to the compressor’s crankcase during the off cycle. This migration of refrigerant is due to a pressure difference between the compressor’s crankcase and the refrigerant. Refrigerant migration can cause the compressor’s crankcase to lose its oil, thus circulating the oil throughout the refrigeration system. This oil in circulation usually gets caught in the evaporator and can cause an oil-logged evaporator.

Refrigerant flooding refers to liquid refrigerant entering the compressor’s crankcase during the on cycle. Flooding can cause flashing of the oil in the compressor’s crankcase because of the liquid refrigerant boiling under the oil. This phenomenon can also cause the compressor to lose its oil and circulate it throughout the refrigeration system. Excessive oil in the system will again get caught in the evaporator and cause an oil logged evaporator. This article will explore the problems associated with an oil-logged evaporator and a compressor’s crankcase low on oil.

Systematic Troubleshooting

Systematic troubleshooting using a system check sheet is still the best method for the conscientious service technician to pinpoint hard-to-find system problems. This article explores how evaporators can become oil logged, and includes symptoms with explanations of a system with an oil-logged evaporator. This refrigeration system incorporates HFC-134a as the refrigerant. It has a thermostatic expansion valve (TXV) for the metering device and a receiver at the condenser outlet.

Listed below are ways an evaporator can become oil logged.

• A flooded compressor circulating oil at start-up;

• Too much oil in the system;

• System not piped correctly (no oil traps or piping too large);

• Liquid migration during off cycle, causing crankcase oil foaming on start-ups;

• TXV out of adjustment (too little superheat causing a refrigerant-flooded compressor);

• Not enough defrost periods for low-temperature application machines; and

• Wrong type or viscosity of oil.

Oil in a refrigeration system has many functions. These functions are:

1. Lubricates;

2. Deadens noise;

3. Transfers heat – cools;

4. Reduces friction;

5. Minimizes mechanical wear; and

6. Seals valves — prevents blow-by in valves and other mechanical parts.

Oil usually logs in the evaporator because it is the coldest component with the largest tubes, thus the slowest refrigerant velocity. Oil logged in the evaporator will coat the inner wall of the coil and reduce the heat transfer through the walls. This will cause a loss of capacity and poor performance. The compressor will be robbed of some of its crankcase oil and run with a lower than normal oil level. This may score or ruin mechanical parts in the compressor.

Too high of a viscosity oil will also be hard to return from an evaporator and will surely cause oil logging. Usually, the heat from the defrost heaters will warm and thin the oil in the evaporator so it can be returned to the compressor once the compressor starts up. This will happen only if the right viscosity (thickness) of oil is used.

If a suction line is oversized, the refrigerant velocity will be decreased. This will prevent the oil from moving through the suction line to the compressor’s crankcase. Remember, it is the refrigerant velocity that will move the oil through the refrigeration system’s piping.

The Check List

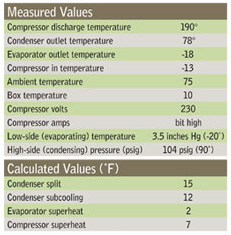

Figure 1 is a system check sheet for an oil-logged evaporator. Pressures and temperatures will vary depending on the severity of the oil logging. Symptoms of an oil-logged evaporator are:

• Noisy compressor;

• Low oil level in sight glass on compressor’s crankcase;

• TXV having a hard time controlling superheat (hunting);

• Low evaporator and compressor superheat; and

• Warmer than normal box temperatures with loss of capacity and lower than normal suction pressure.

Noisy compressor — The compressor may be noisy because of the lack of oil. Metallic sounds may be heard from the lack of lubrication or parts out of tolerance from excessive wear. Oil is a sound deadener as well as a lubricant.

Low oil level in compressor’s sight glass — Because a lot of the oil is in the evaporator, the crankcase will be low on oil. In fact, the entire system’s components excluding the compressor may have too much oil. This would cause a low oil level in the compressor’s crankcase sight-glass. Many times a compressor that is flooding with refrigerant will turn into an oil-pumper. The crankcase will be foaming from the liquid refrigerant flashing in it. Small oil droplets entrained in the oil will be pumped through the compressor. This will oil log many components in the system. The velocity of the refrigerant traveling through the lines and P-traps will try to return the oil from the system to the crankcase. Even an oil separator in the compressor’s discharge line may have a hard time keeping up with excess oil in circulation. However, oil will continue to get into the system if the compressor flooding situation is not remedied.

TXV having a hard time controlling superheat — The TXV will also see too much oil passing through it. The evaporator’s tailpipe will be oil logged and the inside of the tubes coated with oil. The remote bulb of the TXV at the evaporator outlet will have a hard time sensing a true evaporator outlet temperature because of the reduced heat transfer through the line. The TXV will hunt and keep trying to find itself. A constant superheat will not be maintained. The TXV remote bulb may sense a warmer than normal temperature from the oil insulating the inside of the line. This could make the TXV run a low superheat and flood or slug the compressor with refrigerant. Often the sight glass in the liquid line will be discolored with a yellowish or brown tint from refrigerant and oil flowing through it. Technicians may confuse this low superheat reading with an overcharge of refrigerant. However, an overcharge of refrigerant will give high head pressures and high condenser subcooling readings. TXV systems usually can tolerate a bit of an overcharge and still hold a good evaporator superheat if set properly. However, once the head pressures get too high, the TXV will soon overfeed the evaporator and show low superheat.

Low compressor superheat — Because the TXV may be running low superheat, this will cause the compressor (total) superheat to run lower.

Warmer than normal box temperatures with capacity losses — Because of the reduced heat transfer in both the condenser and evaporator from the excess oil coating the inner tubing, capacity will be decreased. The compressor will run longer trying to maintain a desired box temperature. Evaporator temperatures and pressures may run low because of the reduced heat transfer from the oil insulating the evaporator tubes. This will cause reduced mass flow rates and low evaporator pressures.

The service technician must recognize the symptoms brought upon by excessive oil in circulation in a refrigeration system. The service check sheet will be the No. 1 tool in helping the technician recognize that they have this hard-to-detect problem.

Publication date: 8/6/2012

Report Abusive Comment