Timing is everything when it comes to a major urban construction project such as the Huntington Center in Toledo, Ohio. Building the 82-foot-tall arena in the middle of a busy downtown took a lot of planning, and left no room for error.

With the 2009-2010 opening season of the Toledo Walleye ice hockey team looming ahead, contractors frequently worked through the night to stay on schedule to complete the facility. Some of the most critically timed construction phases on the 266,000-square-foot arena occurred before the roof was ever installed.

Bound on all four sides by downtown buildings, the jobsite left no room for material storage during the primary construction phase. Delivery of steel, brick, piping, and other materials had to be carefully timed to arrive precisely as needed.

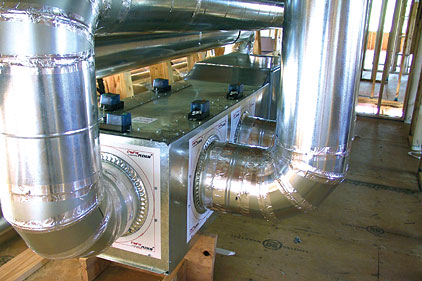

This delivery-upon-demand system applied to the 84-inch diameter double-wall spiral duct by SEMCO, which was specified for the arena space. SEMCO’s spiral duct fittings with AVRON46® provide antimicrobial protection against mold and mildew in an HVAC system. AVRON46 provides the security of an Environmental Protection Agency (EPA) registered fungicide approved for use in HVAC air duct systems, providing protection to an HVAC system and breathable air.

This exposed duct loops around the upper part of the arena just a few feet above the top-tier of seating. To conserve precious vertical space inside, engineers chose to “nest” the massive duct inside the 207-foot-long roof trusses rather than installing it below them. The duct had to be installed in between the trusses in order to leave plenty of clearance for large props and equipment brought in for events like concerts and circuses. The duct was lowered into the truss space by crane before the steel roof decking was installed.

Strategic Delivery

“We had a very short window of time between the truss installation and the roof decking,” said Kenneth Gabel, operations manager, VM Systems Inc. “We had to follow the truss installers weekly in order to get our work completed in time.”

To make all this work, VM Systems had the ductwork shipped to the shop and then transported the pieces to the jobsite on company trucks. The material was lifted by crane from the trucks and directly into the installed space. SEMCO provided the entire length of the pre-insulated, double-wall spiral duct as well as interior duct for the perimeter spaces of the arena. The manufacturer customized rectangular saddle taps to fit inside the round duct. These taps housed the large air diffusers required to direct air all the way to floor level of the arena. The sections of duct were completely prefabricated with special flanges located at optimum intervals. The saddle taps were welded per the engineering firm’s design. Volume dampers and accessories were also factory installed.

Opening Day

Mandell-Vasquez Inc., the SEMCO representative in Toledo, Ohio, worked closely with the manufacturer and the contractor to coordinate these custom fabrications and carefully timed deliveries.

“It was tricky,” said Hernan Vasquez, president, Mandell-Vasquez. “The saddle taps had to be deep because the duct would encase 2-inch thick fiberglass insulation, a heavy duty volume damper, and a large drum diffuser. Of course, everything had to be neatly hidden since this was a completely visible installation.”

All of the duct was fabricated at SEMCO’s manufacturing facility in Roanoke, Va., and was then shipped directly to the jobsite every other day to coincide with the strict installation schedule.

“The material didn’t sit in our yard for more than two days at a time,” said Gabel. “SEMCO had a piece-marked drawing and had to fabricate the duct in the exact same order that it was being installed.”

No Excuses, No Errors

Fans would have had a hard time understanding how a product as commonplace as spiral duct could wreck the completion schedule of the Huntington Center, but according to John Gramke, regional sales manager, SEMCO, it’s not as implausible as one might think. According to Gramke, fabricating large, custom ductwork to the exacting dimensions and shipping within the strict delivery requirements of a project like this is overwhelming for many manufacturers.

“We’ve made custom ductwork a standard at SEMCO. Spot on delivery without compromising quality is something we really focus on. We understand that a delayed delivery can result in a chain reaction of delays that jeopardize the project and cost our customers money,” said Gramke.

“SEMCO has proven its ability to handle carefully timed deliveries in numerous high-profile projects including the famed Lucas Oil Stadium in Indianapolis. It is a defining characteristic of SEMCO manufacturing — one that distinguishes the company in a highly competitive sheet metal market. It is also a tangible benefit to companies like VM Systems who complete hundreds of HVAC installations each year and can’t afford mishaps.

“We work hard at this portion of our business,” said Gramke. “This is why we are consistently chosen for demanding projects like this. It isn’t just about the duct. It’s about the accuracy of coordination, quality of manufacturing, and most important the timely delivery of a product guaranteed to fit.”

Publication date: 8/6/2012

Report Abusive Comment