Too low of a condensing pressure results in too low of a pressure drop across the system’s TXV, which leads to reduced refrigerant flow through the TXV and a starved evaporator. This is not good for overall system operation.

Today there are several methods used to prevent a system’s condensing pressure from falling too low. On systems with multiple condenser fans, one popular method is to cycle them on and off as needed.

Note: This method should not be used on single condenser fan applications. It leads to rapid cycling of the fan motor, wide fluctuations in condensing pressures, and unstable operation.

Cycled Operation

The fans are typically cycled on and off using a “close on rise” pressure control. As the condensing pressure falls, fans are cycled off. As the condensing pressure increases, fans are cycled back on.

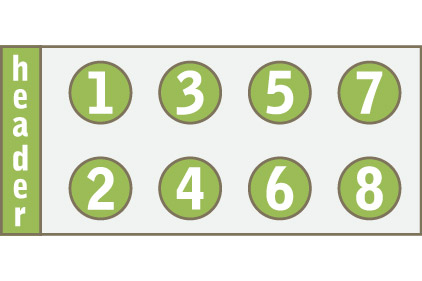

Their operation needs to be staged so that not all of them are cycled off or on at the same time. Fans should be cycled individually; however, if the condenser has two rows of fans, each pair can be cycled together. Also, the fan(s) closest to the header of the condenser should not be cycled off while the compressor is running. This will prevent wide condenser temperature fluctuations that cause excessive expansion, contraction, and metal fatigue. For example, in the sketch, fans 1 and 2 are not cycled; 3 and 4, 5 and 6, and 7 and 8 can be cycled together or individually.

Instead of using a pressure switch to cycle the fans, some systems use a temperature switch. As the outdoor ambient temperature drops, the fans are cycled off. As the outdoor ambient temperature increases, the fans are cycled back on.

Using a pressure switch is more appropriate where the load on the condenser will vary due to multiple compressor operation, stages of unloading, or systems incorporating heat reclaim or hot gas defrost.

Control Adjustments

Proper adjustment of pressure or temperature controls is important to the overall system operation. The controls should be adjusted so the condensing pressure doesn’t fall too low or rise too high; ideally there should be no wide fluctuations in the system’s condensing pressure as the fans are cycled on and off.

It is best to follow the manufacturer’s recommended control settings. As a rule of thumb, fans can be cycled off as the condensing temperature drops below 90˚ and cycled back on as the condensing temperature rises to 110˚. The control’s differential setting needs to be wide enough to prevent rapid cycling of the fans — which will lead to its premature failure.

Fan cycling in excess of three minutes is considered excessive. For pressure controls it is not recommended to set the differential less than 35 psig and for temperature controls not less than 5˚.

Let’s look at a refrigeration system designed with an outdoor air-cooled condenser that has eight fans (two rows of four), a 20˚ TD, and is using HFC-134a as its refrigerant. In this example we will use three pressure switches to cycle the fans — one switch for each pair of fans.

So, fans 1-2 are not cycled off; 3-4 will have a cut-in pressure of 147 psig, 5-6 a cut-in pressure of 155 psig, and fans 7-8 a cut-in pressure of 160 psig. Each of these controls will have a differential setting not less than 35 psig, and may need to be increased to prevent rapid cycling (as long as it does not cause the condensing pressure to drop too low).

This method of head pressure control works well in mild climates. In colder climates it may not be adequate to maintain the system’s condensing pressure. In such a case, this method can be used in conjunction with the flooded condensing to prevent the system’s condensing pressure from falling too low.

Publication date: 09/05/2011

Report Abusive Comment