Bob received a call to go to a convention center where the air conditioning system was not working. It was a 75-ton unit with one compressor. The system was many years old, but had been functioning fine, until now.

Bob arrived and met the building manager. The building manager said, “I have a convention scheduled to start tomorrow morning at 11 a.m. and this system has to be working. Please keep me posted as you go along.”

Bob went to the outdoor unit and noticed that the compressor and fans were not running. He used his meter to check for power and there was none. He then went to the breaker panel and found the breaker to the outdoor unit was tripped. He turned the breaker off and locked out the panel and went back to the condenser control panel. Everything looked normal, so he decided to do an ohm check on the unit. He clipped one meter lead to the cabinet and touched the other lead to the load side of the contactor. It showed 0 resistance to ground. There was a real problem here. Bob looked at the wiring diagram in the unit and saw there were three condenser fan motors and a compressor for the main load with various other components as possibilities for the source to ground.

Btu Buddy showed up and asked, “Do you know what to do next?”

Bob said, “I have to isolate these circuits, one at a time, and find the ground. It seems that if the main breaker is tripped, I should check the biggest load first, the compressor.”

Btu Buddy said, “You are right. Isolate the compressor and see what it is reading.”

Bob isolated the compressor wiring from the contactors and checked it and it was grounded. Bob asked, “How come this compressor has two contactors?”

Btu Buddy said, “I will explain it later. Now, you should concentrate on getting to the bottom of this problem and making a repair.”

Btu Buddy then said, “You have isolated the compressor and its wiring. It could be either one of them reading to ground. You must remove the compressor terminal box cover and remove the leads from the motor before you can actually say that it is the compressor.Be sure and label all wires before you remove them.If you get any of them crossed over, you will really have a problem.”

Figure 1. This is an example of a small single phase compressor that has a partial ground. Our compressor in the service call has a dead short to ground. (From Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Delmar Cengage Learning.) (©Delmar Cengage Learning.) (Click on the image for an enlarged view.)

Bob told the manager about the compressor and the manager asked, “What can I do about tomorrow and the event?”

Bob explained, “There is a compressor rebuild company about two hours from here. They have many models rebuilt on the shelf for quick delivery. It is 4 o’clock now. I believe that I can have a compressor delivered here at 7 a.m. in the morning. They will have to drive it over. I can have everything ready. A crane will have to be here to do the lifting. I can change the compressor in about an hour and have the system on-line by at least 9 a.m.”

The manager gave the word to get started.

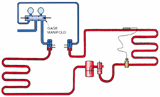

Figure 2. This illustration shows how a compressor can be isolated and removed without losing the charge. (From Refrigeration & Air Conditioning Technology, 6th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Delmar Cengage Learning.) (©Delmar Cengage Learning.) (Click on the image for an enlarged view.)

Bob said, “Yes, and I need to recover the refrigerant that is in the compressor. I can valve the compressor off and only recover the refrigerant that is in the compressor (Figure 2).”

Bob got set up to recover the refrigerant. Before he recovered the refrigerant, he recovered some oil from the crankcase. He checked it for acid and it was clean. There was no need to even change the liquid line filter driers. He then started the refrigerant recovery process. Next he removed the covers to the contactors and found both of them had damaged contacts (Figure 3).

Figure 3. This photo shows some badly worn or burned contacts next to some new contacts. When in this condition, they cannot be resurfaced by filing them down because you will expose the base metal. They have to be replaced. (From Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Delmar Cengage Learning.) (©Delmar Cengage Learning.) (Click on the image for an enlarged view.)

The refrigerant recovery was completed before he left for the supply house. Btu Buddy suggested that he put a holding charge of 5 psig on the compressor.

Bob asked, “Why the holding charge?”

Btu Buddy said, “That is probably just a courtesy to the rebuilder. If you don’t fill the compressor with nitrogen and the compressor has any acid in it from the grounding incident, any air that enters the compressor housing during the changeout will cause almost instant rust inside. You should want to pass this compressor on in as good a shape as you can.”

Bob said, “I agree.”

Bob got to the electrical supply house and picked up the contacts and returned to the job. He then changed the contacts out and was ready for tomorrow, he thought.

Btu Buddy said, “You should run the contactors through a dry run to make sure that they are both functioning. It would be embarrassing in the morning if they did not work correctly after changing the compressor.”

Bob turned the power on and used the building thermostat to start and stop the contactors. They worked fine. He turned off and locked out the power again and connected the lines to the bottom of the contactors.

Bob arrived at the job at 6 a.m. the next morning and had the bolts on the compressor service valves loosened and the compressor hold-down bolts removed when the new compressor was delivered. About that time the crane drove up. Bob showed the driver what he wanted done. The crane got into position.

Bob then disconnected the compressor and moved the service valves back out of the way. He fastened the sling to support the compressor and the crane operator lifted it out of the way and set it on the delivery truck.

The sling was fastened to the new compressor and it was moved into place in the unit where the old one was located. The crane was done, so it left.

Bob put new gaskets on the service valves, furnished by the compressor rebuild company with the rebuilt compressor, and tightened the service valves in place. The new compressor came with blanks over the service ports. He fastened them to the old compressor to keep atmosphere from circulating through the old compressor during transportation.

He then pressure checked the service valves with nitrogen and then let it go to atmosphere and started the evacuation of the compressor housing.

By the time the compressor had been evacuated two times, Bob had all of the wiring connected back and the compressor hold-down bolts back in place. He was ready to back seat the service valves and let system pressure into the compressor. He could then start the compressor.

He had gauges on the compressor when he started the back seat process with the valves, so now he could observe the pressures on start up.

Bob made sure that that he could control the unit from the low voltage at the outdoor unit. He placed an ammeter on one of the lines feeding the unit and turned on the disconnect. The unit did not start because he had a low voltage wire disconnected. He connected the low voltage wire and the unit started.

The compressor started right up and the pressures were reading what they should. It was now 8:45 a.m. The manager heard the unit start up and came outside and said, “I couldn’t believe yesterday that you could get this job done as you explained. I had a speech ready for you and now I am going to have to change it to say, a job well done.”

Bob said, “Thanks. All of the pieces fell into place at the right time.”

Bob observed the system while it pulled the building temperature down. Finally, he said to Btu Buddy, “Now explain to me why two contactors and all of those wires?”

Btu Buddy said, “I will save that until we meet again. How about lunch tomorrow?”

Bob said, “OK, at the same restaurant.”

Publication date:06/20/2011

Report Abusive Comment