Click on the image for an enlarged view.

CAUSES OF SHEAVE WEAR

A simple acronym can help in remembering the key dynamics of sheave wear - TIME. It breaks down as follows:• Tension

• Installation

• Maintenance

• Environment

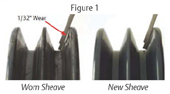

Figure 1. Click on the image for an enlarged view.

EXPLANATION

Tensionis often a leading cause of efficiency loss and leads to sheave wear. If belts are undertensioned, they slip in the groove of the sheave. As a drive starts and stops, the constant slipping decreases belt life and erodes sheave grooves. A tension checker is recommended for all installations and maintenance procedures to help ensure adequate tension.Installationmust be done correctly to avoid sheave wear. Technicians need to ensure that sheave alignment is achieved. Bushings must be properly installed so appropriate engagement with the sheave and shaft occurs. Failure to properly install a bushing can cause wobble and vibration. Even a slight wobble can cause premature sheave wear.

Maintenanceis a critical element to minimizing sheave wear. Technicians need to ensure that preventive maintenance programs/schedules incorporate inspection of driver and driven sheaves. Technicians should check for proper alignment, installation, and tension. Note: Sheaves having greater than 1/32 inch wear need to be replaced. (See Figure 1.) A sheave gauge is an excellent tool for identifying sheave wear.

Environmentis an often overlooked contributor to sheave wear. Technicians need to ensure that belt guards are properly installed and that debris is not falling into the drive path. Abrasive airborne contaminants such as sand and rock dust can destroy belts and quickly erode sheaves. If contaminants are ultimately unavoidable, a routine cleaning of sheaves should be performed to minimize wear.

VIDEO AND REFERENCE GUIDE

Browning has developed a 12-minute belt drive tensioning video that covers all aspects of sheave installation, maintenance, and proper belt tensioning. The video is viewable on the web at www.emerson-ept.com. In addition, a 120-page Belt Drive & Bearings Reference Guide (Form # 8932) covers proper maintenance procedures as well as troubleshooting information.Reprinted with permission from the Browning Belt Drive Monthly published by Emerson Industrial Automation. For more information, visit www.emerson-ept.com.

Publication date:10/18/2010

Report Abusive Comment