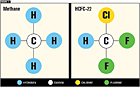

Figure 1

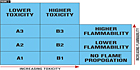

R-22 is a pure compound containing only one molecule. It is not a refrigerant blend. The R-22 molecule contains hydrogen (H), carbon (C), chlorine (Cl), and fluorine (F). Its chemical name is chlorodifluoromethane, meaning its molecule has one chlorine atom, two fluorine atoms, and its base molecule is methane (Figure 1). R-22 is classified as a hydrochlorofluorocarbon (HCFC). Its safety classification is A1, meaning it is very low in toxicity and has no flame propagation (Figure 2).

APPLICATIONS

R-22 has been the primary refrigerant used in commercial and residential air conditioning systems for many years. It has also been used in large, industrial, centrifugal chiller air conditioning applications. Industrial cooling processes also use R-22 in their equipment. R-22 is currently replacing CFC-502 in some low-temperature commercial supermarket refrigeration applications, although HFC-404A seems to be the leader in this category.A high heat of compression, thus a higher discharge temperature, is a characteristic of the R-22 molecule when compressed. So, when R-22 is used in low-temperature commercial refrigeration applications, compound compression (often with interstage cooling) is used to help decrease the compression ratio and cool the higher discharge temperatures associated with R-22 in these low-temperature applications.

R-22 is also used in some medium-temperature commercial refrigeration and supermarket applications.

Figure 2

OZONE DEPLETION

Because the R-22 molecule contains chlorine, it has an ozone depletion potential (ODP). When released into the atmosphere, some of the HCFC molecules could reach the stratosphere and damage the ozone layer that shields the earth from the sun’s harmful ultraviolet (UV) radiation. This UV radiation causes skin cancers and other malignant melanomas, decreases crop yields, kills certain marine organisms, and damages other biological systems.As mentioned earlier, HCFCs contain chlorine, but they also have hydrogen in their molecule that makes them less stable in the atmosphere. HCFCs have much less potential than CFCs for ozone depletion because they have a tendency to break down easier in the lower atmosphere (troposphere) before reaching a higher atmosphere (stratosphere), where good ozone resides. The weaker hydrogen bond in their molecule is responsible for this easier breakdown of the molecule.

However, some HCFC molecules do reach the stratosphere. Eventually, their chlorine atoms within the molecule will get broken off. This chlorine atom will soon react with an ozone molecule in the stratosphere and change its composition. This depletion of the ozone molecule allows UV radiation to reach the earth.

GLOBAL WARMING

Most of the sun’s energy reaches the earth as visible light. After passing through the atmosphere, part of this energy is absorbed by the Earth’s surface and, in the process, is converted into heat energy. The Earth, now warmed by the sun, radiates heat energy back into the lower atmosphere toward space.

Naturally occurring gasses and tropospheric pollutants like CFCs, HCFCs, HFCs, carbon dioxide, water vapor, and many other chemicals, absorb, reflect, and/or refract the Earth’s infrared radiation and prevent it from escaping the lower atmosphere. These gases are often referred to as greenhouse gases. This process slows the Earth’s heat loss, making the earth’s surface warmer than it would be if this heat energy could pass unobstructed through the atmosphere and into space. The warmer Earth’s surface, in turn, radiates more heat until a balance is established between incoming and outgoing energy. This warming process is called global warming or the greenhouse effect, and it takes place in the lower atmosphere, or troposphere.

All refrigerants in the CFC, HCFC, or HFC categories have a global warming potential (GWP). Because HCFCs have both an ozone depletion and global warming potential, as of July 1, 1992, it became illegal to intentionally vent HCFC refrigerants to the atmosphere. Today, it is illegal to vent CFCs, HCFCs, and HFC into the atmosphere.

Global warming can be divided into two categories: direct effect and indirect effect.

A direct effect of global warming is created by chemicals like CFCs, HCFCs, or HFCs that are emitted directly into the atmosphere. These direct emissions are measured by an index referred to as the refrigerant’s GWP. Leaking refrigerant from a refrigeration or air conditioning system is a good example of something that has a direct effect on global warming.

An indirect effect of global warming has to do with the efficiency of the refrigeration and air conditioning system. The more efficient the system is, the less electrical energy is needed. Even refrigeration or air conditioning equipment with a relative small charge of refrigerant that never leaks out may have a great impact on global warming if the equipment is undercharged or overcharged.

The inefficiency causes longer run times and more electrical energy usage. This inefficient equipment causes more carbon dioxide to be generated from the longer run times. Carbon dioxide is the No. 1 global warming gas because it’s a byproduct of the fossil fuel combustion used for much of the generation of electricity in the U.S. The extra carbon dioxide generated for the extra electricity generated from an overcharge or undercharge, or any other system problem (like a dirty condenser or evaporator), will contribute to global warming more than the refrigerant leaking out. Many refrigeration or air conditioning system problems may create higher amp draws, higher power usage, and/or longer run times and contribute to the indirect effects on global warming.

System problems may include:

• Dirty condenser.

• Dirty evaporator.

• Frosted coil.

• Wrong refrigerant.

• Inefficient compressor.

• Wrong line set size.

• Too long of refrigerant lines.

• Condenser fan out.

• Evaporator fan out.

• Undercharge.

• Overcharge.

• Dirty or clogged filter-drier.

• Wrong TXV setting for superheat.

• Air in the system.

• Moisture in the system.

• Mixture of refrigerants.

• Low on oil.

• Too much oil.

Naturally occurring gasses and tropospheric pollutants like CFCs, HCFCs, HFCs, carbon dioxide, water vapor, and many other chemicals, absorb, reflect, and/or refract the Earth’s infrared radiation and prevent it from escaping the lower atmosphere. These gases are often referred to as greenhouse gases. This process slows the Earth’s heat loss, making the earth’s surface warmer than it would be if this heat energy could pass unobstructed through the atmosphere and into space. The warmer Earth’s surface, in turn, radiates more heat until a balance is established between incoming and outgoing energy. This warming process is called global warming or the greenhouse effect, and it takes place in the lower atmosphere, or troposphere.

All refrigerants in the CFC, HCFC, or HFC categories have a global warming potential (GWP). Because HCFCs have both an ozone depletion and global warming potential, as of July 1, 1992, it became illegal to intentionally vent HCFC refrigerants to the atmosphere. Today, it is illegal to vent CFCs, HCFCs, and HFC into the atmosphere.

Global warming can be divided into two categories: direct effect and indirect effect.

A direct effect of global warming is created by chemicals like CFCs, HCFCs, or HFCs that are emitted directly into the atmosphere. These direct emissions are measured by an index referred to as the refrigerant’s GWP. Leaking refrigerant from a refrigeration or air conditioning system is a good example of something that has a direct effect on global warming.

An indirect effect of global warming has to do with the efficiency of the refrigeration and air conditioning system. The more efficient the system is, the less electrical energy is needed. Even refrigeration or air conditioning equipment with a relative small charge of refrigerant that never leaks out may have a great impact on global warming if the equipment is undercharged or overcharged.

The inefficiency causes longer run times and more electrical energy usage. This inefficient equipment causes more carbon dioxide to be generated from the longer run times. Carbon dioxide is the No. 1 global warming gas because it’s a byproduct of the fossil fuel combustion used for much of the generation of electricity in the U.S. The extra carbon dioxide generated for the extra electricity generated from an overcharge or undercharge, or any other system problem (like a dirty condenser or evaporator), will contribute to global warming more than the refrigerant leaking out. Many refrigeration or air conditioning system problems may create higher amp draws, higher power usage, and/or longer run times and contribute to the indirect effects on global warming.

System problems may include:

• Dirty condenser.

• Dirty evaporator.

• Frosted coil.

• Wrong refrigerant.

• Inefficient compressor.

• Wrong line set size.

• Too long of refrigerant lines.

• Condenser fan out.

• Evaporator fan out.

• Undercharge.

• Overcharge.

• Dirty or clogged filter-drier.

• Wrong TXV setting for superheat.

• Air in the system.

• Moisture in the system.

• Mixture of refrigerants.

• Low on oil.

• Too much oil.

• Partially plugged TXV, capillary tube, or orifice metering device.

• Inappropriate coil matching.

• Inappropriate coil matching.

TEWI

The total equivalent warming impact (TEWI) takes into consideration both the direct and indirect global warming effects of refrigerants. Refrigerants with the lowest global warming and ozone depletion potentials also have the lowest TEWI.Often, the chemical makeup of the refrigerant or refrigerant blend itself will give it certain properties that are more efficient than the refrigerant it is replacing. Most of the newer refrigerants and blends introduced into the HVACR industry are more energy efficient than the ones they are replacing.

An example of this is HFC-410A replacing R-22 in new (OEM) air conditioning equipment. HFC-410A featured greater capacities, higher efficiencies, and a lower TEWI than other HFC candidates for air conditioning applications. R-410A allows the OEM to improve system performance, while addressing new energy (13 SEER and environmental ODP, GWP and TEWI) standards.

PHASEOUT SCHEDULES

Even though HCFCs have lower ODPs than chlorofluorocarbons (CFCs), that wasn’t low enough, especially for the European mindset. So, the United States began a phaseout schedule of HCFCs. In fact, the Montreal Protocol was modified in 2007 and the HCFC phaseout schedule was accelerated. Here is a history and timeline of this gradual phaseout schedule:

1987: Montreal Protocol sets reduction rates for HCFCs and other ozone depleting substances.

1992: Illegal to intentionally vent HCFCs into the atmosphere.

1994: Mandatory technician certification for servicing a/c or refrigeration equipment.

1996: Capping of HCFC levels under the Montreal Protocol goes into effect.

2004: HCFC refrigerant production reduced by 35 percent.

2007: HCFC reduction on production accelerated from 65 percent to a 75 percent reduction on production from the baseline production year of 1989.

2010: R-22 is banned in new equipment (OEM level).

2015: A 90 percent cap on R-22 production from the baseline production year of 1989.

2020: Total ban on R-22 production.

These accelerated rulings affect so-called developed countries such as the United States, Canada, and countries in Europe. Also under the new agreement, developing countries such as China, India, and Mexico will now phase out production of new equipment using HCFCs by 2030 instead of 2040. Also, these countries will more rapidly phase down the use of such refrigerants.

These new rulings mean that all new refrigeration and air conditioning equipment produced in the United States will be required to use a zero-ODP refrigerant. In addition to these environmental regulations, all new air conditioners will be required to meet a minimum SEER of 13, meaning a “greener” future for our environment.

1987: Montreal Protocol sets reduction rates for HCFCs and other ozone depleting substances.

1992: Illegal to intentionally vent HCFCs into the atmosphere.

1994: Mandatory technician certification for servicing a/c or refrigeration equipment.

1996: Capping of HCFC levels under the Montreal Protocol goes into effect.

2004: HCFC refrigerant production reduced by 35 percent.

2007: HCFC reduction on production accelerated from 65 percent to a 75 percent reduction on production from the baseline production year of 1989.

2010: R-22 is banned in new equipment (OEM level).

2015: A 90 percent cap on R-22 production from the baseline production year of 1989.

2020: Total ban on R-22 production.

These accelerated rulings affect so-called developed countries such as the United States, Canada, and countries in Europe. Also under the new agreement, developing countries such as China, India, and Mexico will now phase out production of new equipment using HCFCs by 2030 instead of 2040. Also, these countries will more rapidly phase down the use of such refrigerants.

These new rulings mean that all new refrigeration and air conditioning equipment produced in the United States will be required to use a zero-ODP refrigerant. In addition to these environmental regulations, all new air conditioners will be required to meet a minimum SEER of 13, meaning a “greener” future for our environment.

RETROFIT BLENDS FOR R-22

Which is the best retrofit refrigerant blend for R-22? This is probably the most frequently asked question by contractors, equipment owners, and technicians. Unfortunately, this question cannot be answered directly because it depends on several key factors:• Evaporator temperature application (air conditioning or refrigeration).

• Application of the equipment (design capacity and run time for the application).

• Equipment size (ease of retrofit or service).

Because of these key factors, neither no one solution, nor no one retrofit refrigerant blend, will handle all applications.

Next month’s article will address these three key factors and give some insight on retrofitting with refrigerant blends.

Publication date:08/03/2009

Report Abusive Comment