SYSTEM MAINTENANCE

The best way to ensure that an HVAC system, whether using bare metal or internally insulated ductwork, will continue to provide efficient, quiet air delivery, and occupant comfort is by following a regular system operation and maintenance schedule. This, along with a high-efficiency filtration system, assures protection of both HVAC system components and building occupants. Maintenance procedures include inspection, detection, and remediation of probable sources of airborne contaminants and moisture.As always, prevention is the most desirable solution. However, in some cases, it may be too late for prevention and system cleaning is necessary. If duct cleaning is necessary, it is important that the cleaning professionals be familiar with both the North American Insulation Manufacturers Association (NAIMA) and National Air Duct Cleaning Association (NADCA) guidelines. Today’s air duct insulations are designed to withstand the rigors of cleaning.

Figure 1. Contact vacuuming method.

CLEANABILITY

Fiberglass duct liner and duct board products have surfaces that are resistant to the kind of abuse that occurs during duct cleaning. NAIMA has worked with NADCA and the U.S. Environmental Protection Agency (EPA) in developing guidelines for cleaning insulated ductwork. Currently, there are several cleaning methods available. The NAIMA recommended methods of duct cleaning include:Contact Vacuuming

This method involves the use of a portable vacuum with high efficiency particulate air (HEPA) filtration (Figure 1). There is direct contact between the brush head and the interior of duct surfaces to dislodge and remove dirt and debris.

Figure 2. Air washing method.

This method introduces compressed air into the duct through a hose terminated with a “skipper” nozzle, while the duct system is under negative pressure (Figure 2). This nozzle is designed so that the compressed air propels it inside the duct while dislodging dirt and debris. The dislodged dirt and debris become airborne, and are drawn downstream through the duct and out of the system by the vacuum collection equipment.

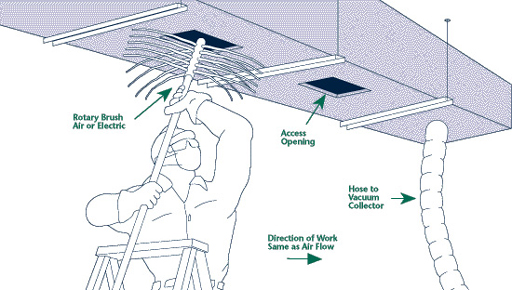

Figure 3. Power brushing method.

This method involves the use of pneumatically or electrically powered rotation bristle brushes to loosen dirt and debris, which are drawn downstream into a vacuum collector (Figure 3). Care should be taken not to damage the duct walls or insulation surfaces. Only flexible bristle brushes should be used.

REMEDIATION

If it has been determined that the HVAC system has physical damage or excessive contamination present on the airstream surface of the fiberglass duct liner or duct board, then remediation is required.When indoor environmental quality (IEQ) problems arise, an assessment may be made of the performance and conditions of HVAC system components including the materials that are exposed to the airstream surface. The assessment may find physical damage or excessive contamination present in the airstream surface of the fiberglass duct liner or duct board. If this is the case, then remediation is required.

Duct liner or duct board materials meet strict Underwriters Laboratories (UL), National Fire Protection Association (NFPA), and American Society for Testing and Materials (ASTM) standards and do not require an additional field-applied sealant or encapsulants other than those recommended by the manufacturers. As a result, these materials are not required to have field-applied sealants or encapsulants applied to the airstream surface by either fabricators or installers.

Sealants

During remediation, a sealant should only be used if the damage to the airstream surface is small and localized. If it has been determined that the damage or contaminated surface can be remediated by the application of a sealant, care should be taken to assure that the sealant is compatible with the coating or facing materials used by the manufacturers to protect the airstream surface of the duct liner or duct board materials. Consult the insulation manufacturer to assure that the sealant is compatible with the insulation material.

Sealant Must Meet Codes

The selected sealant needs to meet the building code requirements and be handled and installed following the application and safety recommendation provided by the manufacturer. Other important information, such as long-term longevity and durability, should be addressed with the sealant manufacturer.

Installation and Application

For a sealant to be effective, it is important that it be applied correctly. The manufacturer of the sealant should be consulted for their installation recommendation. The information should include the application steps required to achieve the coverage needed for the sealant to be effective.

Direct application of the sealant to the damaged surface has been determined to be the only effective way to achieve complete coverage of the damaged area. Spraying a sealant into the airstream will not provide the needed coverage to the damaged surface.

Sanitizers and Biocides

The EPA regulates the use of sanitizers or biocides inside ducts that either kill or inhibit microbial growth. The EPA has recommended that disinfectant, sanitizer, or other antimicrobial products not be applied to HVAC systems if such product does not include specific directions for HVAC use.

The EPA noted that even where labels do list HVAC systems as a possible use, they are concerned that the risks of these uses have not been fully evaluated. In addition, they warn that users of these products cannot assume that EPA registration of these products reflects any conclusion about their safety or effectiveness in HVAC systems.

NAIMA recommends that building owners or managers who are considering the application of sanitizers or biocides be aware of a number of issues related to their use in HVAC systems. Some manufacturers of these products may be required to make Material Safety Data Sheets (MSDS) available upon request. If applicable, you should review the MSDS for health and safety information related to these products. Additional information on the use of biocides and sanitizers is also available on the EPA Website.

Reprinted with permission from the Air Handling Issues page of the North American Insulation Manufacturers Association (NAIMA) Website. For more information, visit www.naima.org.

Publication date:04/06/2009

Report Abusive Comment