Figure 1. This is a gas package unit that uses electricity for air conditioning and gas for heat. (Figures are from Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Delmar Cengage Learning.)

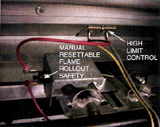

He removed the control panel and was looking around when he saw that the flame roll out switch had a manual reset button (Figure 2). He pushed the button and the unit started up. The flame looked normal. A few moments later, the circulating fan came on and the flame began to roll out of the heat exchanger. He used the breaker to shut the unit off for further inspection. It seemed like the fan was pressurizing the heat exchanger and pushing the flame out of the heat exchanger.

Bob then took the top off of the unit so that he could access the heat exchanger and fan section. He removed the fan so that he could see the heat exchanger (Figure 3). When he examined it, there were some holes in it where the tubes had been formed. There was the problem.

Figure 2. This is an example of a flame roll out control with manual reset. (Click on the image for an enlarged view.)

Bob started the unit. The burners all lit as they should and looked to be burning great. The fan then came on and everything looked fine. He then shut the unit off and replaced all the panels and screws and turned the unit on again. He told the owner all was well, and he left.

Bob got back to the shop and the owner called and said the unit had shut off again. He didn’t know what to think about that, so he headed back out to the house.

When he arrived, he went into the house and tried the thermostat ‘fan on’ switch and the fan did not start. He decided that he must have some sort of power problem, so he went outside to investigate. He removed the panel to the burners and all looked well. He looked up and noticed the 40-amp breaker to the unit was in the tripped position. Now what?

He reset the breaker, and the unit came on. He was thinking that a random breaker trip had occurred for some reason when it tripped again and sparks flew from the control panel.

Figure 3. Here is a heat exchanger similar to the one in the service call. Note that it is made from bent tubing.

Bob explained what had happened.

Btu Buddy then asked, “What are you going to do now?”

Bob answered, “I am going to reset the breaker and see if I can see where the sparks came from.”

Btu Buddy said, “That is what a ‘spark-trician’ would do. Don’t you think you should look around first?”

Bob said, “I was afraid you would take that attitude, but you are right. I may do more damage if sparks are flying. I will see what I can find with an ohmmeter.”

Bob gave the control panel a good visual examination and could find no sign of where the sparks came from. He thought there should be some sign of burn, but there wasn’t.

He then used his ohmmeter on the RX1 scale and placed one lead on a screw head for a good ground source and used the other lead to see if he could find a connection to ground. There was a ground showing on the high voltage side of the compressor and condenser fan, but that should have no bearing on the heating side, but Bob disconnected the compressor terminals and checked the compressor, no ground there. He then checked the condenser fan and found no ground there.

He noticed that the compressor contactor only had one set of contactors which meant that the compressor and fan circuit had one leg of power to them at all times. Bob asked Btu Buddy, “What is with the contactor with one leg of power hot all the time?”

Btu Buddy explained, “This uses a less expensive contactor and is sometimes used to energize the crankcase heat only during the off cycle. More on that subject at a later time. Let’s repair this one now.”

Bob then asked, “What do we do now? We can’t seem to find a ground that would cause a breaker to trip.”

Btu Buddy then said, “Get where you can see the control panel and turn the breaker on again. I believe it will work now.”

Bob turned the breaker on and the burner started up again. All seemed normal. They were standing there when all of a sudden, sparks flew from the control panel and the breaker tripped again.

Bob said, “I saw where the sparks came from.” He went to the breaker and made sure that it had tripped on both legs. He turned it off and went back to the unit and said, “The sparks came from under there.” He looked under the control panel and found one of the wires that was running to the condenser fan was welded to the frame of the unit.

“Here is our problem,” Bob said.

He pulled the wire loose and patched it, and then he said, “I should have noticed that these wires were too close to the heat exchanger. These wires are not high temperature wires; they are ordinary wire.”

Btu Buddy then said, “Well, that solved the problem and explains the time delay which allowed the furnace burner to start and for the unit to be able to run for short periods of time. When the furnace got hot, it melted the insulation. That wire was just touching down until that last cycle which welded it to the frame.”

Bob said, “Boy, what a problem and we still found it by the ‘spark-trician’ method. That was all we could do. Good thing that I was able to see where the spark came from.”

Btu Buddy responded, “You are a good observer and that is important in being a good troubleshooter.”

Publication date:12/22/2008

Report Abusive Comment