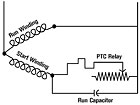

Figure 1. PTC relay with start capacitor

The circuit is wired so that the PTC thermistor is wired in series with the start winding of the motor (Fig. 1). If the motor requires a start capacitor, it will also be wired in series with the start winding and PTC relay. When the motor starts, the resistance of the thermistor will initially be very low and sufficient current will flow through the PTC thermistor, the start winding and/or start capacitor to allow the motor to start normally. As the current flows through the PTC thermistor, it will quickly heat up and its resistance will quickly increase to a point where the current flow will dramatically reduce, essentially removing the start winding and/or start capacitor from the circuit.

Another use for a PTC relay is with a permanent split capacitor (PSC)-style compressor. These compressors are designed to operate with a run capacitor in the motor circuit to give them better running efficiency. Sometimes these compressors will require the addition of a start capacitor to assist the starting of the compressor. Normally a potential relay will be used to disconnect the start capacitor from the circuit. However, a PTC relay can also be used for the same purpose. There are two ways in which a PTC relay can be used to assist in starting a PSC-style compressor.

Figure 2. PTC relay with run capacitor

The other method is to use the PTC relay with a start capacitor (Fig. 3). The PTC relay is wired in series with a start capacitor, and both the PTC relay and start capacitor are wired in parallel with the run capacitor. During the starting of the motor, both the start and run capacitors are in the circuit to assist in starting the motor. Once the thermistor heats up, the start capacitor is essentially removed from the circuit and the motor runs normally.

Figure 3. PTC relay with start and run capacitor

Troubleshooting these relays is normally simple. Remove the relay from the circuit and allow it to cool to room temperature. Place an ohmmeter across the terminals of the relay. At room temperature, the measured resistance should be low. If an infinite resistance is measured the relay needs to be replaced.

Publication date:09/01/2008

Report Abusive Comment