The dispatcher sent Bob to a new customer for a routine system tune-up. The system was a 3-ton cooling unit with a capillary tube metering device.

Bob looked the system over and thought everything was in good shape. The customer was not really complaining about system performance, but the weather was not really hot, only 85°F. Bob felt the suction line and it did not feel quite as cool as it should be, so he fastened a temperature tester to the suction line and it read 60°. Bob thought that was a little high so he decided to increase the head pressure by blocking the condenser and see what happened to the suction line temperature.

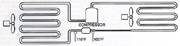

Figure 1. Blocking some of the airflow across the condenser causes the head pressure to rise. This will make sure the condenser is not backing up refrigerant and the metering device will get the correct amount of liquid only. This illustration shows normal conditions when the condenser is blocked on a cool day. (Figure is from Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Delmar Cengage Learning.) (Click on the image for an enlarged view.)

Bob then decided to fasten gauges to the system. The high-side gauge read 275 psig with the condenser still blocked and the low-side gauge read 51 psig. Bob knew this was not right since the low-side temperature in the evaporator corresponded to 27° for 51 psig suction pressure. The system used R-22 for the refrigerant.

Bob was scratching his head when Btu Buddy appeared and asked, “What is the problem, Bob?”

Bob said, “This system’s pressures don’t add up. With a head pressure of 275 psig, the suction pressure should read about 70 psig.”

Btu Buddy asked, “What is the superheat at these conditions?”

Bob said, “It is 28° with the condenser blocked. The suction pressure is low; the super heat is high with a normal head pressure for a hot day. The low-side symptoms show a low charge.”

Btu Buddy then asked, “What are you going to do?”

Bob said, “Add refrigerant.”

Figure 2. This infrared thermometer can be used to take the surface temperature of many substances. (Figure is from Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Delmar Cengage Learning.)

Bob then said, “Well, a partially plugged capillary tube would starve the evaporator and act like this system.”

Btu Buddy then said, “You may be on the right track. Start looking for reasons that the low side is starved of refrigerant. Are there other reasons?”

Bob then said, “The capillary tube must have a good quality of liquid refrigerant entering it for it to perform correctly.”

Btu Buddy said, “You may have something there. How would you check for that?”

Bob said, “The system doesn’t have a sight glass, so I am not sure.”

Btu Buddy then suggested, “How about temperature of the liquid line. You can use your infrared thermometer to check the liquid line temperature (Figure 2).”

Figure 3. The liquid entering the drier is 110°F and it is 100° when it leaves. There is a 10° temperature drop across the drier. When there is a temperature drop, there is a pressure drop. The drier is partially restricted. (Figure is from Practical Cooling Technology by William Johnson, published by Delmar Cengage Learning.) (Click on the image for an enlarged view.)

Bob said, “Wow, there is a temperature drop across the drier. It must be partially plugged.”

Btu Buddy said, “See if you can tell the difference in temperature across the drier with your hands.”

Bob felt both sides of the line to and from the drier and said, “No, they feel the same to me. I would think that I could feel a 10° temperature difference.”

Btu Buddy said, “Some people may be able to feel the difference, but the difference is hard to detect with just your touch. Now what?”

Bob said, “It is going to be hard to explain to a customer that there is a problem when they don’t see a symptom.”

Btu Buddy said, “You are right about that, but you owe it to the customer to try.”

Bob explained to the customer that the drier was partially plugged and that it was hard on the compressor to operate without proper cooling, and that the first time hot weather came, the system would not cool the home.

The customer said to go ahead with the repair.

Bob recovered the refrigerant from the system, changed the filter drier, and recharged the system. He used scales to recharge the system to the correct charge and then checked the system again. The condenser was still blocked and the evaporator showed 12° of superheat with 278 psig of head pressure. The condensing temperature was 125° and the liquid line temperature was 113°, which is 12° of subcooling. The system was in good working order.

Btu Buddy suggested, “Leak check all connections, including the service port where you removed the gauges, before you count the job completed.”

Bob completed the leak check and all was well.

As they were riding away, Bob said, “Well, another lesson learned.”

Btu Buddy added, “The lessons go on and on, that is why this is such an interesting profession. I have heard people say that this is a profession for people who don’t have the intellect to go to college. That service call was for a thinking person.”

Publication date:10/20/2008

Report Abusive Comment