The dispatcher called Bob to go to a new customer who was complaining about a rumbling noise that her furnace was making when it shut down.

Bob arrived at the job which was a dress shop out in the country. The customer’s furnace used fuel oil. The season was just getting cold enough that the store required heat in the morning. Bob talked to the owner to try to get the picture of what was going on. She said, “The burner starts up and runs fine, but when the thermostat shuts the burner off, there is a rumble at the furnace.”

Bob went to the furnace and looked around. Everything seemed normal. He turned the furnace off at the switch on the unit and went to the thermostat and pushed the heat indicator up to call for heat. Then he went back to the furnace and started it up. The burner started normally and after awhile, the fan came on. The furnace seemed to be operating normally. He let it run until it was warmed up to typical operating temperature and then he shut the switch off. The burner stopped running, but then there was a low rumble that sounded frightening.

Bob then told the storeowner that he believed the furnace needed a good tune-up and a nozzle change. He asked her, “How long has it been since the unit has had service?”

She said, “I change the air filters on a regular basis, but the furnace has not been serviced in about two years.”

Bob explained, “It pays to have an oil furnace serviced every year. There are many intricate moving parts in an oil furnace and the fuel oil filter and nozzle need to be changed every year. The efficiency can slowly creep down and you will not know it.”

She then said, “Go ahead and do a full service on the system. We need all the efficiency we can get out of the system with oil prices like they are.”

Bob changed the nozzle and oil filter and put his gauge on the oil burner to see what the oil pressure was while running. He got his combustion analysis kit out to check the combustion and the flue draft. Then he started the furnace; the oil pressure was 100 psig. He let the furnace get up to temperature, then checked the draft over the fire and it was -0.05, which was good. Bob then did a smoke test, which showed minimum smoke. The combustion analysis showed the furnace to be operating at 75 percent efficiency. Everything really looked like the furnace was doing its job, so he shut it off thinking all was solved, and the rumble sounded off again.

Bob was standing there looking confused when Btu Buddy appeared and said, “You don’t look happy about this.”

Bob said, “I thought I had the problem whipped with a new nozzle and it is still rumbling.”

Btu Buddy asked, “What do you think could cause the rumble?”

Bob said, “It is obvious that there is some sort of after-burn going on. I just don’t know why.”

Btu Buddy then asked, “What is supposed to stop the oil flow at the end of the burner cycle?”

Bob then said, “I think there is something in the pump that should shut the oil supply off at some pressure.”

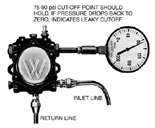

Figure 1. This photo shows the approximate cutoff point of oil pressure to the nozzle at shut down. (Figure is from Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Delmar Cengage Learning.) (Click on the image for an enlarged view.)

Bob went to his truck and looked up service procedures and found the answer.

Bob told Btu Buddy, “The oil pump is supposed to furnish 100 psig to the burner while operating and shut the oil off at about 80 psig (Figure 1) at shut down. I am going to run this system through another cycle.”

Btu Buddy said, “Good idea.”

Bob started the system again and all seemed normal. He let it run for a few minutes and shut the switch at the furnace off and looked at the oil gauge that he had previously installed. The gauge went all the way to 0 psig when the furnace stopped and the rumble was still there.

Bob then said, “That is the problem. Now what can I do to fix it?”

Btu Buddy explained, “You can either change the pump or install a solenoid valve in the small oil line between the pump and the nozzle. The solenoid will be wired in parallel with the pump motor. A new pump is the more expensive option. Another thing that can cause after fire drip and rumble is air in the nozzle. You would think that 100 psig of oil pressure would push an air bubble through the oil nozzle, but sometimes it won’t and when the burner shuts down, the air will expand and push oil out into the combustion chamber and a rumble will occur. Tell me the procedures you used to change the nozzle.”

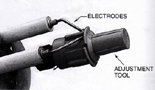

Figure 2. This plastic gage is used to set the electrodes in the correct position for oil burners. (Figure is from Practical Heating Technology by William Johnson, published by Delmar Cengage Learning.) (Click on the image for an enlarged view.)

Btu Buddy said, “You did the critical thing by filling the nozzle holder and tube with oil. There should not be any air left in the system.”

Bob went to the supply house and got a small solenoid for the oil line and installed it.

Btu Buddy said, “You have let in some air while adding the solenoid. Run the furnace one time and push the air bubble to the nozzle and it may move all the way out. If you still have after-burn, you may have to remove the nozzle tube assembly and remove the nozzle and fill the nozzle holder again. Let’s run the burner and see what happens.”

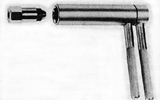

Figure 3. This photo shows an oil burner nozzle wrench. It is the only type of tool that should be used to remove or tighten an oil burner nozzle. It can be operated with one hand and will hold the nozzle holder and the nozzle at the same time. (Figure is from Practical Heating Technology by William Johnson, published by Delmar Cengage Learning.)

Bob said, “Well, I guess that is all.”

Btu Buddy said, “You really should start and stop the burner two or three more times just to be sure.”

Bob did what Btu Buddy said and the burner performed correctly.

Bob then told the owner what he had done and that the burner sounded great. As they drove away, Bob said, “Well, there is another lesson learned, thanks to you.”

Btu Buddy then said, “Just keep learning those lessons one at a time and over time you will have quite a lot of experience to draw from.”

Publication date:11/17/2008

Report Abusive Comment