When I arrived, the service guy met me in the driveway. He immediately began telling me all about the problem. He explained that someone else had installed a circulator, but that it hadn’t helped much with the lack-of-heat problem. I suggested we start in the basement and we headed for the stairs.

The first thing I checked was the piping. I know that pipes have to be large enough to carry the heat from the boiler to the radiators. That’s something a lot of guys overlook when they’re faced with a problem. Here, however, the piping looked fine. The new fitter had taken great pains to mimic the original fitter’s piping techniques. The branch line to the new addition took off from the main at the correct angle. It was the same as the branches that fed the other first-floor radiators. The size was right, and everything else in the basement looked okay.

I talked to the homeowner, and she told me most of the house heated well. “It’s just the addition,” she said. “We’ve been cold for the past two years. We need some answers, and we need them fast!”

I asked her if the radiators in the addition got warm and she said they did, but the room was still uncomfortably cold. I started to suspect there might not be enough radiation in the new addition.

“What’s the heat loss in the addition?” I asked the service guy.

“Seventeen-thousand Btu,” he said.

I checked out the two new radiators.

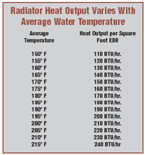

Together, they put out 90 square feet EDR. I divided the heat loss of the new addition (17,000 Btu/hr) by the square foot EDR. Those radiators would have to have 190°F flowing through them before they’d heat that space. And since most hydronic systems work with a 20° temperature difference from supply to return, the boiler would have to run up to 200° to satisfy the load.

Click on the chart for an enlarged view.

So how much radiation did we need to add to the addition? Well, a lot depended on the average water temperature flowing through the rest of the house. The homeowner told me the rest of the house was comfortable, so we ran a heat loss calculation on the living room and came up with 21,000 Btu/hr. The installed radiation in the living room was 175 square feet EDR. Again, I divided the heat loss by the installed EDR and came up with 120 (21,000 ÷ 175 = 120). That meant the radiators in the living room were providing comfort by putting out 120 Btu/hr per square foot.

Looking at the chart, I could see this corresponded with an average water temperature of 155°. No wonder they didn’t have enough heat in the new addition! The water wasn’t hot enough. The original installer had designed this system to run on relatively low-temperature water (165°) because he was using a coal-fired boiler. Low temperature water was the norm in the days of gravity hot water heat.

If we raised the boiler water temperature to satisfy the addition, we would have made the rest of the house uncomfortably warm. We also would have increased the homeowner’s fuel bills. That’s why we decided to add an additional 52 square feet EDR to the addition.

We figured this out by dividing the heat loss of the addition by the heat output we’d expect to get from 155° average water temperature (17,000 Btu/hr heat loss ÷ 120 Btu/hr/square foot = 142 square feet EDR required). We already had 90 square feet installed; the additional 52 would bring us up to 142 square feet EDR, and that’s exactly what we needed to bring the addition in line with the rest of the house.

Once we had this figured out, we suggested to the homeowner that she put the new addition on its own zone. We explained how this would give control over the system and take her from the 1920s into the 21st century in a hurry. She liked the idea and gave us the go ahead.

I sized a B&G Series 100 circulator for each zone. The 100 provides the large flow/low head characteristic you need for a gravity conversion job. I added two B&G Flo-Control valves, one for each circulator, to prevent gravity circulation to a heat satisfied zone. I also had the installer pipe in a bypass to protect the boiler from thermal shock.

The system works beautifully now!

Reprinted with permission from the ITT Bell & Gossett newsletterCounterPoint™,Volume 12, Issue 1. For more information on hydronic systems, visit the ITT Bell & Gossett Website at www.bellgossett.com.

Publication date:11/19/2007

Report Abusive Comment