The dispatcher called Bob and said, “A customer called and his heat pump is not running. The customer reset the breaker at the outdoor unit several times, and it just tripped again.”

Bob told the dispatcher to call the customer and tell him to switch the unit to emergency heat and to not reset the breaker again.

When Bob arrived, he talked to the owner. The owner told Bob that the unit was working just fine last night but was not working this morning when he got up. Bob explained that he should really have not reset the breaker but one time, as it really stressed the breaker to keep resetting it.

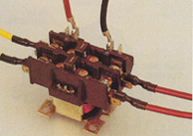

Figure 1. This contactor has the line voltage coming in one side and the load voltage to the compressor out the other. The two wires standing straight up are control wires. (Figures are from Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Thomson Delmar Learning.)

Bob then went to the owner and explained to him that he had to turn off the main breaker for a few minutes because the breaker on the unit was defective. He explained to the owner that shutting off the main breaker would shut down his computer if it was operating. The owner asked to have five minutes so he could shut down the computer. The owner then came back and told Bob that the computer was off. The owner asked, “Is that the only problem?” Bob said, “I don’t know. I have to be able to work without any power to the unit to determine that.”

Bob then went to the main panel and turned off the main breaker. He then changed the defective breaker at the unit and turned the main breaker back on and notified the owner that he was through with the main circuit.

Bob was now ready to troubleshoot the unit. With the breaker to the unit off, he placed his ohmmeter leads on the load side of the breaker and set the ohmmeter to RX1. The reading was infinity. All looked good up until now. He then removed the panel to the unit’s electrical components and pushed the armature to the contactor to close the contacts (Figure 1). The meter reading was 10 ohms. He then placed a meter lead on the load side of the contactor and the other to a ground source. The meter read 0 ohms, a dead short to ground. Now he was getting somewhere. He now had to decide where the short was located.

Figure 2. This grounded compressor only shows 100 ohms to ground. The one in the service call shows 0 ohms to ground. (Click on the image for an enlarged view.)

Bob had found the problem and told the owner that he would pick up the necessary supplies and be there in the morning. As he was picking up his tools, Btu Buddy arrived and said, “How are you going to leave the unit until tomorrow?”

Bob said, “Just put the panel back on and leave the breaker off.”

Btu Buddy noted, “If you leave the power off to the crankcase heater, the compressor will be full of refrigerant. The refrigerant will be mixed with the oil and recovery will be hard to accomplish. Whatever you do, leave the crankcase heat on. Tape the compressor leads where they are safe and turn the breaker back on.”

Figure 3. A capacitor tester can be used in the field to determine the capacitance of a capacitor.

Bob said, “A compressor and refrigerant.”

Btu Buddy asked, “How about the contactor and the run capacitor? They were stressed also.”

Bob then said, “I am not really thinking this all the way through, am I?”

Btu Buddy said, “No, there are many items that must be considered when there is a motor shorted. For example, you do not know if it is a motor burn, or just a wire shorted to ground.”

Bob then asked, “What should I do next?”

Btu Buddy answered, “You could run an acid test on the system to determine if there are acids present. Do you have one of those acid test kits that you can pass some refrigerant through for a test?”

Bob said, “No.”

Btu Buddy then said, “We will just have to wait until we take the old compressor out and look at the piping for signs of burned oil and smell. We may need a suction line acid removing filter in addition to a liquid line filter drier. Put them on the list; we will use both if needed.”

Figure 4. Good contacts are shown next to contacts that are pitted and should be replaced.

He then gave the contactor a visual check by looking at the contacts. They looked bad (Figure 4). He then added a contactor to the list of supplies.

Btu Buddy then said, “I think you have all the bases covered. Leave the power on and replace all of the covers.”

As they were riding away, Bob said, “There are a lot of details to doing a job correctly. How do you ever remember them all?”

Btu Buddy said, “Well, you remembered one of the first details. You reminded the owner that you were going to shut off the power and to shut down the computer. Some technicians would just shut off the power. If the owner was uploading or downloading business files and had no battery backup for the computer, it could cause grief for him. He would be mad about that. These things become instinct as you gather more experience. You are doing well with your training.”

Bob then said, “Thanks, I feel as though I still need a lot of training.”

Btu Buddy responded, “Training is a forever thing in a good technician’s life.”

Look for Part 2, “Btu Buddy 49: Grounded Compressor Motor (Continued),” in the April 23, 2007 issue of Extra Edition.

Publication date:03/19/2007

Report Abusive Comment