Figure 1. Typical fan coil unit that may have a chilled water circuit for cooling and a hot water circuit for heating. (From Practical Heating Technology, by William Johnson, published by Thomson Delmar Learning.) (Click on the figure for an enlarged view.)

The dispatcher sent Bob to a motel that is five stories high with the complaint that the top floor did not have any heat. It was 30°F outside. People were having to move to the lower floors to stay comfortable, creating an expensive problem for the motel.

Bob arrived and asked the manager to explain what he knew about the problem. The manager said, “Late last night the front desk began to get complaints about it being cold on the top floor. By morning, it was obvious that we had a problem.”

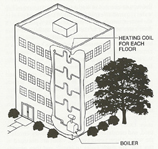

Bob went to the equipment room in the basement where the boiler was located for a look around. He discovered that it was a hot water boiler with one hot water pump that serviced the entire building. The boiler was hot, the pump was running, and the sound of water circulating was noticeable. Everything seemed OK at the boiler.

Figure 2. This is a thermal action zone valve. It is not a snap acting valve but has a 24 V heat motor inside. It is very quiet in its action as opposed to a solenoid snap acting valve. (From Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Thomson Delmar Learning.)

Bob explained to him what he had checked up to now and Btu Buddy said, “It sounds like you are on the right track. You said you went to the boiler room and the boiler was hot. Did you check the entering and leaving temperatures?”

Bob said, “No, I bet that would be something good to know.”

They went to the boiler room and the leaving temperature at the boiler was 190°F and the return water temperature was 160°F. Bob said, “There seems to be plenty of heat, but it is not getting to the fifth floor.”

Btu Buddy suggested, “I suspect there is air in the system. If air gets into the water side of the system, it will naturally go to the top and water will not circulate. Let’s go to the top floor and see what we can find.”

They went to the fan coil unit that Bob checked before and Btu Buddy said, “Use your screwdriver as a ‘poor man’s stethoscope’ to see what you can hear in the piping (Figure 3). If there is any water circulating, you should be able to hear it.”

Figure 3. We call this a poor man’s stethoscope. It is used to listen for vibration or water flow. (From Practical Heating Technology, by William Johnson, published by Thomson Delmar Learning.) (Click on the figure for an enlarged view.)

Btu Buddy then said, “Let’s find the high point in the piping and see if we can find an air bleed valve. The piping normally runs to the top floor and then branches out to the various circuits, and there should be a bleed valve on the supply riser and the return pipe. It would save time if we could see the blueprints of the building. Let’s go to the office and see if they have them.”

They went to the manager and he got out the prints. They found that the bleed valve was behind an access panel in the ceiling on the fifth floor.

Btu Buddy said, “Get a length of flexible plastic tubing and a step ladder from your truck and a bucket to catch the bleed water to keep it off of the motel carpet.”

Bob returned with the flexible tubing and a bucket and they found the removable panel and the bleed valve and made the connection.

They connected the bleed line to the valve and let the end down into the bucket and were ready to bleed the air (Figure 4).

Figure 4. The system includes a bleed valve at the high point in the system. This system is a closed loop of water pipe and the air will go to the highest point in the system. (From Practical Heating Technology, by William Johnson, published by Thomson Delmar Learning.) (Click on the figure for an enlarged view.)

After several minutes, water began to go into the bucket. The water was really rusty and dirty. Bob said, “Boy, the tube and bucket were a good idea. This rusty water on this red carpet would not look good. Motel management would not be happy.”

Btu Buddy said, “Your company might not be invited back if that happened. The rust color would be hard to remove.”

The water became hot after a few minutes. Btu Buddy then said, “Now bleed the return line to make sure that all of the air is out of the system. Then leave the bucket, ladder and tube here. We have more investigation to do. First, let’s see if we have heat now.”

They went to the two rooms that they had previously checked and found hot air coming out of the fan coil units. Bob said, “Well, thanks to you, we are through and all is well.”

Btu Buddy then said, “Most technicians would leave the job now, but I think that we should find the cause of the air in the system. If we walk out now, it is likely to occur again. You have to go on another call, so let’s meet back here tomorrow and solve the problem.”

Bob asked, “Will the system run like it should until tomorrow?”

Btu Buddy said, “Yes, this air accumulation is most likely over a period of time. This is a closed loop piping system, so air will be slow to accumulate. Get your ladder and leave the bucket and tube above the ceiling and put the access panel back until tomorrow.”

Bob explained the problem to the manager and told him that he would be back in the morning.

Look for Part 2, “Btu Buddy 47: How Air Gets Into a Hot Water Heating System,” in the Feb. 19, 2007 issue of Extra Edition.

Publication date:01/22/2007

Report Abusive Comment